Research Summary Report of A01

Particle-Bed 3D Printing by Selective Cement Activation (SCA) – Sustainability, process enhancement and material models

[14.10.2025]

Herding, Friedrich; Researcher, friedrich.herding@tum.de

Lowke, Dirk; Project leader, lowke@tum.de

Technical University of Munich, Chair of Materials and Methods in Digital Construction

Main Goal

Our primary research goal is to develop a comprehensive understanding of the interactions between material and process in Particle Bed 3D Printing (PB3DP) using Selective Cement Activation (SCA). This knowledge will enable us to fabricate concrete elements with high mechanical strength and dimensional accuracy. We are also examining various strategies for reinforcement integration, which are essential for producing load-bearing structural components. Furthermore, we are investigating ways to reduce the cement content in the particle mix and enhance the durability of printed specimens.

Summary

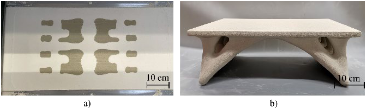

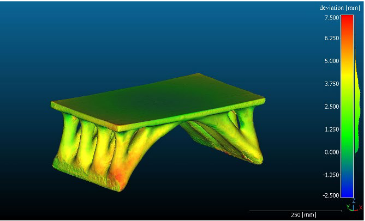

A small-scale bridge-like demonstrator, shown in Figure 1, was manufactured based on the design of the C02 project. Here, we explored the potential of printing shape- and topology-optimised geometries. The element was scanned using a laser scanner. Afterwards, the resulting point cloud was compared with the digital model of the slab, showing a mean deviation of 1.92 mm from the digital model, as shown in Figure 2. This was attributed to the capillary transportation effects of the water in the particle bed, resulting in the water flowing out of the designated area into the surrounding particle bed. The deviations on the bottom side were larger than those on the top side. Around the supports, occasional deviations of up to 7 mm were measured.

The results of this study demonstrate the potential of combining intricate design with digital fabrication. Based on state-of-the-art structural optimisation, a concrete building component was additively manufactured. However, the results also indicate that further research is needed. Especially, the control of the water imbibition into the particle bed is one of the

challenges.

In our current research, we focus on the integration of reinforcement into SCA-printed components. Two integration strategies are investigated:

1. The integration of reinforcement during the process. Here, glass- or carbon fibre grids with a height less than the layer height of 1 mm are placed onto the activated particle bed as interlayer reinforcement.

2. The subsequent integration of reinforcement after the component has been printed. In this method, reinforcement is inserted into specifically designed channels that have been intentionally left inactive. After the inactivated material is removed and the reinforcement inserted, the channels are filled with a grouting mortar. Recent experimental series have focused on the effect of local w/c-ratios in the vicinity of the reinforcement on the mechanical strength of flexural beams. First results indicate an increase in strength with increasing w/c-ratios.

Wüchner, R., Warnakulasuriya, S., Asl, R.N., Bletzinger, K.-U., D’Acunto, P., Herding, F., Lowke, D., 2024. Free-form Structural Optimization for Additive Manufacturing in Construction. Digital Concrete 2024 – Supplementary Proceedings.

https://doi.org/10.24355/dbbs.084-202408200656-0

Fiigure 1: a) Printing of the demonstrator with

activated (dark grey) and inactivated areas (light grey)

of the particle bed and b) shape- and topology-

optimised slab element / Credit: Wüchner et al., 4th

Digital Concrete 2024

Figure 2: Scan of the printed slab and dimensional

comparison with the digital model / Credit: Wüchner et

al., 4th Digital Concrete 2024