Research Summary Report of A02

Particle-Bed 3D Printing by Selective Cement Paste Intrusion (SPI) – Particle Surface Functionalisation, Particle Synthesis and Integration of WAAM Reinforcement

[10.09.2025]

Hamilton, Leigh Duncan; Doctoral Researcher, L.Hamilton@tu-braunschweig.de

Zetzener, Harald; Leading researcher, H.Zetzener@tu-braunschweig.de

Kwade, Arno; Project Leader, A.Kwade@tu-braunschweig.de

TU Braunschweig, Institute for Particle Technology

Main Goal

To enable selective paste intrusion (SPI) for practical applications, including reinforcement is mandatory. The focus of the first funding period was uniting SPI with wire arc additive manufacturing (WAAM) for reinforced concrete as well as functionalising and/or modifying applied materials. During the first funding period, two main issues were identified: the need for ecological sustainable development for the combined process of SPI+WAAM and accelerated process velocities to improve the economic efficiency. Therefore, the main goals of the project A02 for the second funding period are optimising ecological materials for SPI and reducing the required number of welding operations within the WAAM process.

Summary

A substantial part of developing sustainable material options is recycling available and otherwise discarded concrete components. Envision circular factories in which demolished concrete is separated into highly pure individual material components and subsequently fed straight into an SPI printer. Such concepts are conceivable for the near future. However, recycling concrete in a manner that is adequate for SPI is not a trivial task. For instance, recycled aggregates – mainly coarse sand or gravel – must allow the cement slurry to fully penetrate a previously deposited aggregate layer, thereby ensuring proper bonding between layers. As of yet, replacing cement with recycled cement only works until a certain degree for SPI in terms of process technology. Therefore, we have been investigating various process steps to recycle concrete materials from concrete components with the goal of defining preparation strategies for a specific material outcome and desired reusable product. Our starting point involves concrete components created by SPI or according to a similar recipe. These components are recycled as well as separated in-house by crushing, milling, sieving, and classifying processes. Recycling SPI components has two main advantages for our research: 1) The concrete mixture including additives is well known for subsequent analysis, 2) Life cycle assessments for SPI products will reveal the true potential of its sustainable development. Especially for the prior, knowing the composition helps derive the required crushing or milling dynamics for ideal recyclability. It is, nevertheless, of great significance to ensure recycled particles conform to requirements for SPI.

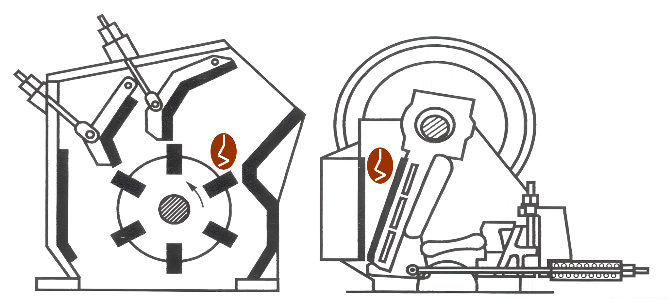

Small-scale experiments were performed starting with cylindrical test specimens with a diameter and length of 60 and 100 mm, respectively. The specimens were mixed using a standard SPI recipe and three different aggregate sizes were applied, ranging from 0.7 to 3.2 mm. Two types of crushers were used, namely an impact and a jaw crusher (illustrated in Figure 1).

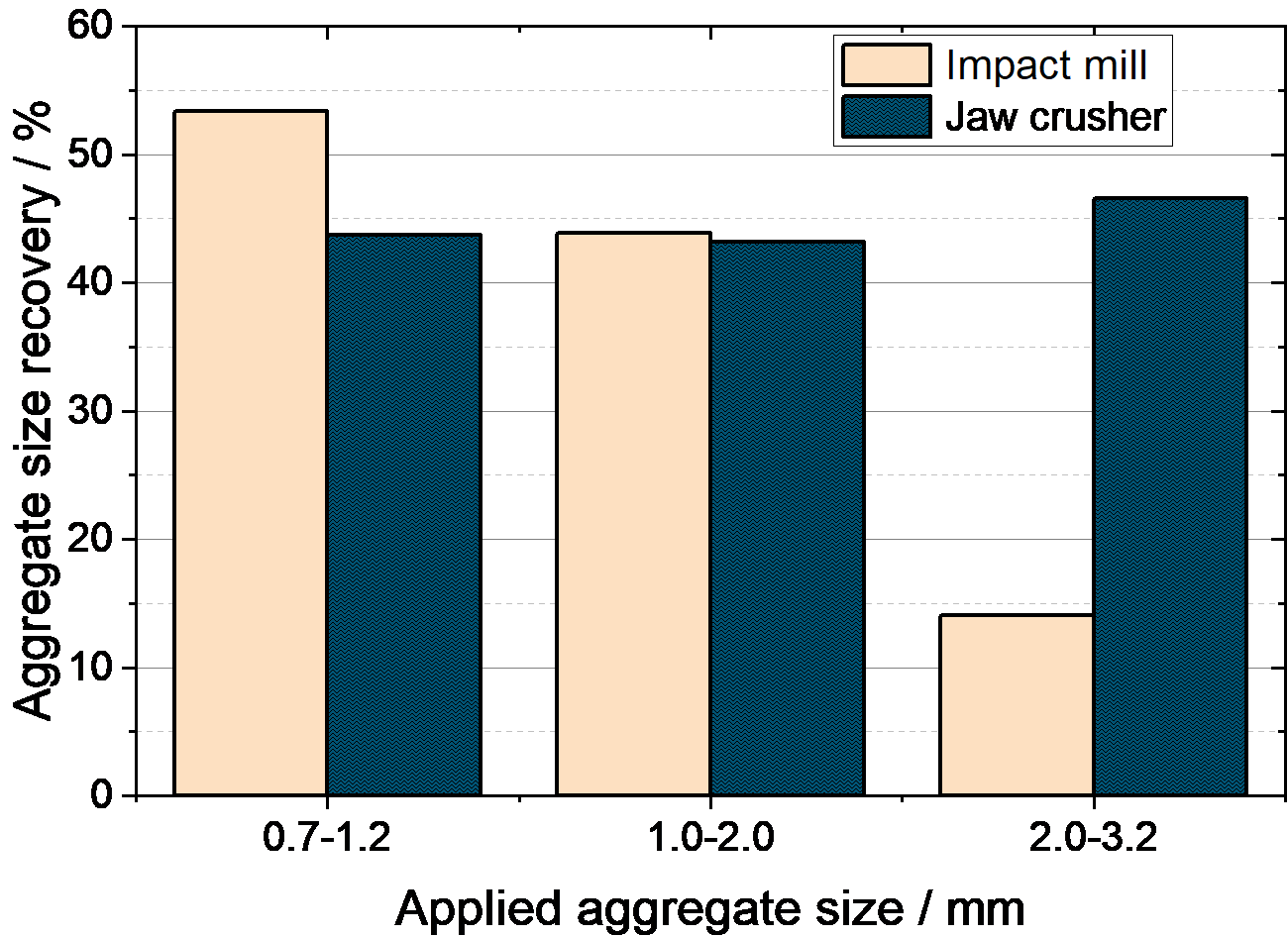

These devices differ by the way they stress particles. An impact crusher strikes feed materials at high velocities on one surface, similar to hitting a baseball with a bat. A jaw crusher, on the other hand, pressurises material between two surfaces which resembles chewing on food with your back teeth. Hence the name, jaw crusher. Figure 2 shows the percentage of recovered aggregates for two crushers and the applied aggregate size.

Noticeably, the recovery rate in an impact mill depends highly on the aggregate size, whereas it seems indifferent for the jaw crusher. Furthermore, the impact mill produced impurities and a sizeable proportion of fines, meaning aggregate particles were also crushed in the process. Keep in mind: when it fractures, there is no going back. Seeing as we aim to restore each individual material, this is not favourable. Hence, taking a gentle approach results in higher grade material outcomes. Sieve cuts larger than the aggregate size were applied to a double-roll mill (see Figure 3), recycling additional material.

Figure 1: Impact crusher (left) and jaw crusher (right) with an illustrative particle in the device showing where and how it is stressed. / Credit: Schubert, Handbuch der mechanischen Verfahrenstechnik.