Research Summary Report C04

Integrating Digital Design and Additive Manufacturing through BIM-Based Decision Support and Digital Twin Methods

[25.03.2022]

Li, Chao; doctoral researcher, chao1.li@tum.de

Petzold, Frank; PL, petzold@tum.de

Technical University of Munich, TUM School of Engineering and Design, Chair of Architectural Informatics

The application of Additive Manufacturing (AM) methods in the construction process requires the careful consideration of its applicability and the necessary boundary conditions in the early design phase of construction. Project C04-WP1 aims to conceive a design decision support system (DDSS) to integrate AM technologies in the early design phase. The DDSS allows the analysis of the early-stage building design regarding the geometric features and functional properties of the individual components and provide recommendations for the manufacturing method.

Summary

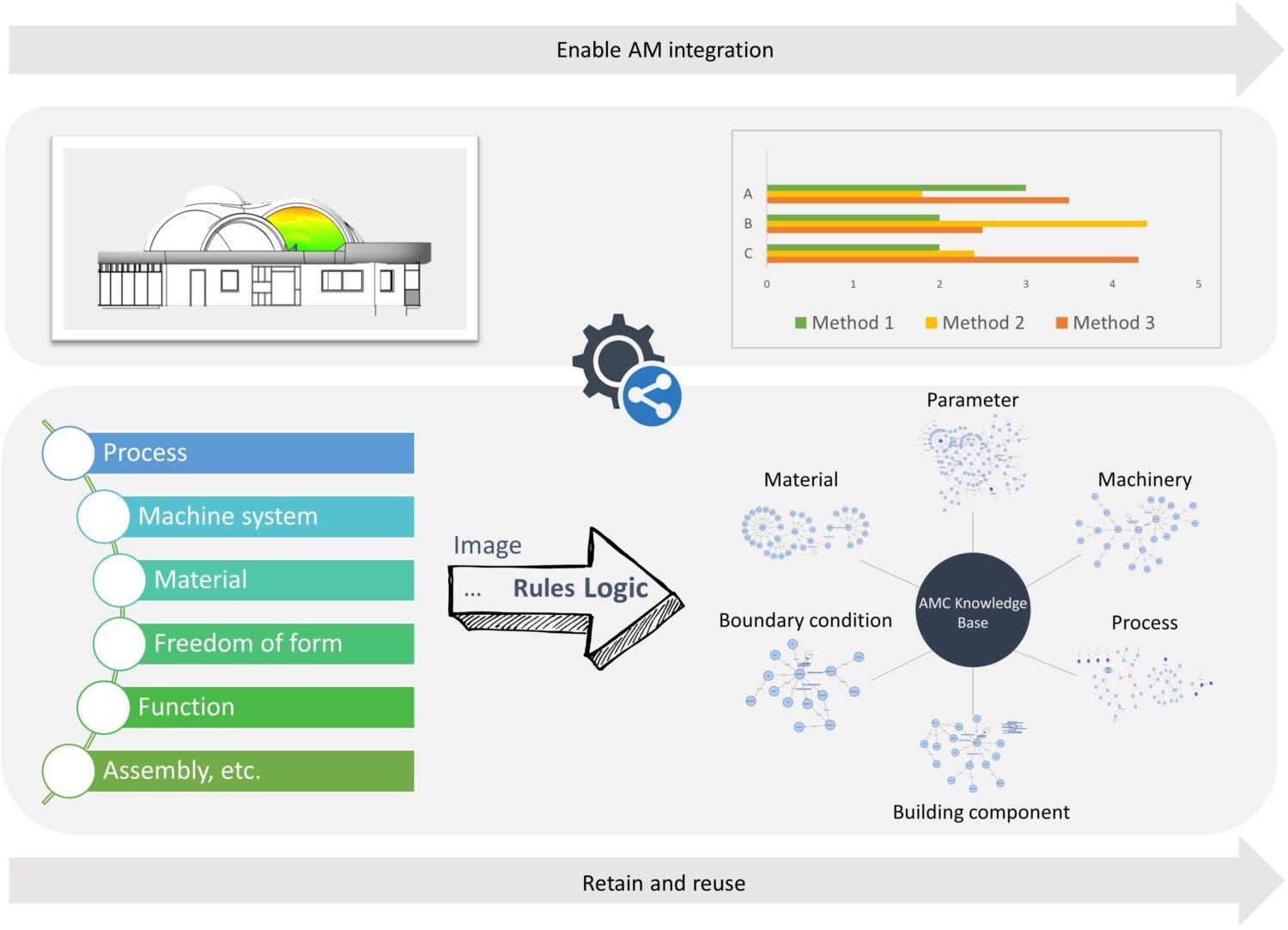

Consideration of AM methods in early design stages can be enabled by a user-centered DDSS integrating formalized, machine-readable AMC knowledge. In terms of geometry analysis, manufacturing features are extracted and compared to the codified boundary conditions of different AM methods. Data transfer between parametric modeling software and DDSS can be realized by a platform-independent communication protocol. Applicability of AM is inferred through dedicated “reasoner” which can deduce fulfillment of regulations and AM methods’ boundary conditions w.r.t the geometry and semantics of individual building components. Afterwards, detected disruptions of boundary conditions and rules (e.g., max. overhang degree and max. shipping dimension) will be visualized against design constraints for intuition of design adaptation. Complexity and AMC and meta of the knowledge base can be seen briefly in Figure 1.

In order to resolve the mingling and often contradicting design criteria throughout the decision-making process, depending on multiple user-defined design criteria, the DDSS will adaptively provide interactive Multi-Criteria-Decision-Making (MCDM) routines with proper visual and textural explanations.

Current state of research

Currently, the prototypical DDSS is able to assert AM methods’ applicability in terms of material conformity, workspace sufficiency and manufacturability regarding to several geometry features. Ontologies of AM methods have been updated in accordance with the iterative process of knowledge management. Update-to-date information of geometry constraints, mechanical and physical properties have been codified into the knowledge base.

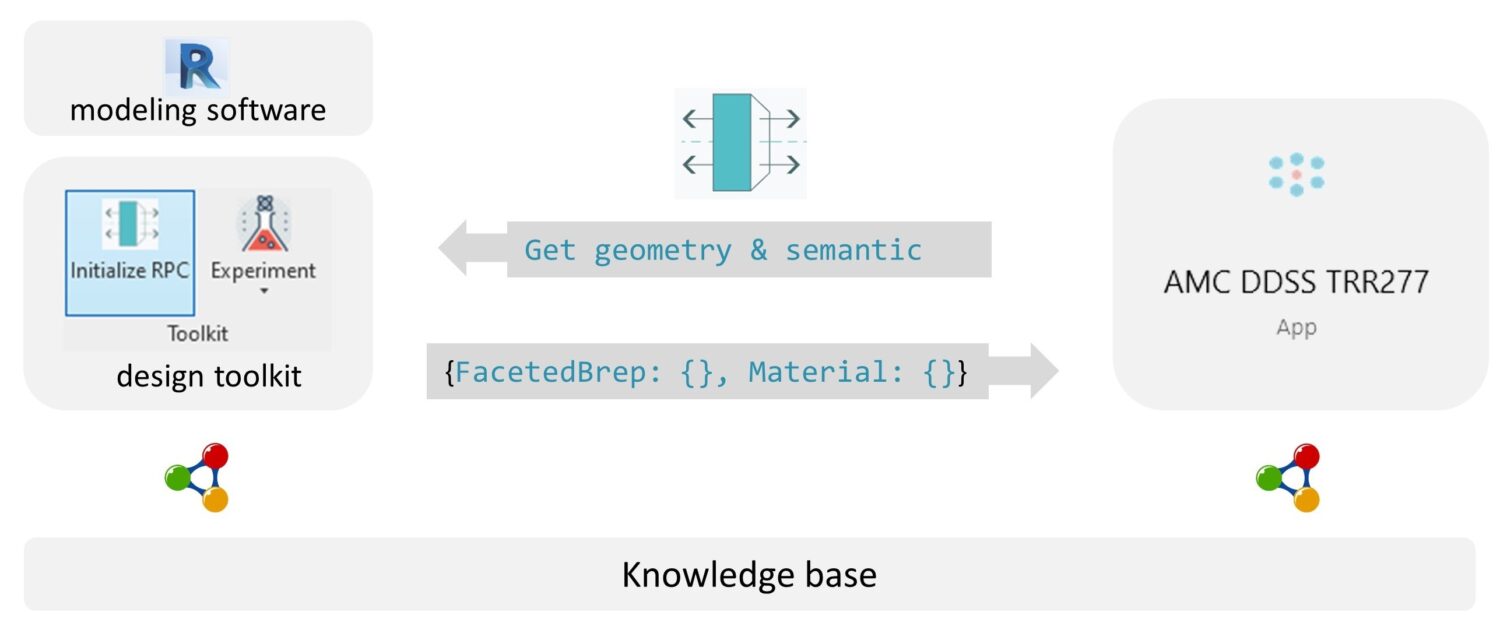

For the sake of interoperability with different modeling software, client-server fashioned Remote Procedure Call (RPC) framework has been deployed such that other modeling software could interact with DDSS as well. Corresponding system architecture is illustrated in Figure 2.