Research Summary Report C04

Integrating Digital Design and Additive Manufacturing through BIM-Based Decision Support and Digital Twin Methods

[05.03.2021]

Li, Chao; Doctoral researcher; chao1.li@tum.de

TU Munich, Chair of Architectural Informatics

Slepicka, Martin; Doctoral researcher; martin.slepicka@tum.de

TU Munich, Chair of Computational Modeling and Simulation

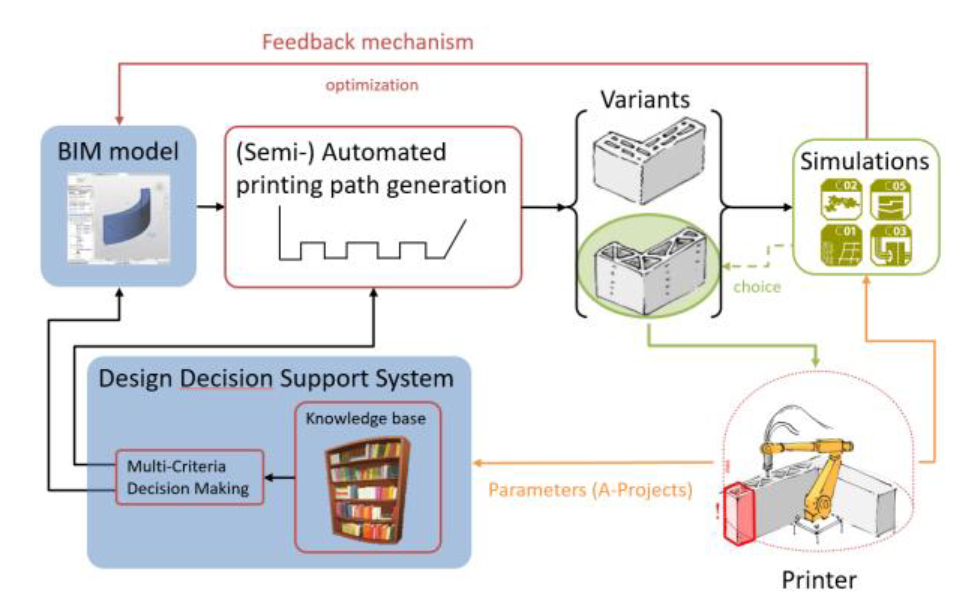

In the context of AMC, C04 workgroups attempt to cohesively integrate AM and BIM–based early design, through the design decision support and fabricationenhanced multi–LOD BIM models.

Knowledge Base Formalization Domain–specific knowledge base usually serves as a backbone in a Knowledge–Based System (KBS).

Furthermore, the knowledge base of proposed DDSS has to be formalized in an extensible, reusable and interoperable manner. In the first stage of work, C04 workgroups have conducted semi–structured interviews between other sub–projects (A01–A05, C01–C06). From the interviews, four groups of knowledge have been initiated while need to be updated iteratively. Accordingly, Semantic Web technology stack has been chosen by WP1 to approach the formal description of AMC–specific knowledge, for its capability, over the individual Knowledge Representation (KR) techniques, to holistically embody rules, ontology, knowledge querying and reasoning[1][2]. To prove the workability of integrating Semantic Web based knowledge into BIM authoring system, a Revit add–in has been developed to query the preliminary AMC–related ontology through the dotNetRDF[3]. Up to now, basic queries from code–behind to the knowledge base turned out a success, which paves the road of upcoming milestones. As inspired from Design for Additive Manufacturing (DFAM) ontologies, adaptations of the initialized knowledge base is under work. Basically, the new ontology aims to loosely couple manufacturability of a building component from its form and function while intermediating those using parameters, manufacturing features and design rules.

Automatic derivation of fabrication information from a BIM model

Both BIM–based design and additive manufacturing processes describe the same object once it has been manufactured, but design focuses more on the final form and function of the component and AM processes focus more on the manufacturing process itself. In the construction industry, the two disciplines are currently handled separately, even though a common database and mutual integration would be beneficial in create a continuous digital chain from design to the finished product [4]. In the field of mechanical engineering, this is realized by linking Computer Aided Design (CAD) and Computer Aided Manufacturing (CAM) processes in uniform software solutions and further improved with the extension of the exchange data format STEP to STEP–NC, to contain a database for the numerical control of machine tools [5]. This makes it possible, for example, to be informed about possible conflicts or obstacles caused by manufacturing processes directly during the design phase [6].

To integrate design decision support and an automated system to derive fabrication information into the BIM–workflow we propose a new methodology, the Fabrication Information Modeling (FIM). As an iterative workflow (shown in Fig. 1), it enables an efficient integration of AM information and workflows into BIM, starting from the early design phase.