Research Summary Report A06

Integration of Individualized Prefabricated Fibre Reinforcement in Additive Manufacturing with Concrete

[19.02.2021]

Rothe, Tom; Doctoral researcher, t.rothe@tu-bs.de, TU Braunschweig, Institute of Mechanics and Adaptronics (IMA)

Hühne, Christian; Project leader, christian.huehne@dlr.de, TU Braunschweig, Institute of Mechanics and Adaptronics (IMA)

One of the biggest challenges in 3D printing with cementitious materials is the integration of reinforcement. The project aims to develop textile-based reinforcement strategies for additive manufacturing with concrete and to utilize the advantages of textile reinforcement (e.g. corrosion resistance and material flexibility) for the production of material-efficient, individualized structures. These structures should be produced by a robotic winding process, which provides a high degree of freedom in shaping in combination with a minimal amount of tooling and formwork. To be able to do so, a highly autonomous production process is required. Therefore an in situ fiber preparation is integrated. Within this process, fiber rovings are formed to strands. Furthermore, the fiber preparation includes the resin impregnation and the application of a helix surface structuring by wrapping a secondary yarn around the preformed strands to increase the interlocking between the reinforcement structure and the concrete.

Besides their structural task, the winded reinforcement meshes serve as a base for additively applied concrete. Different methods for applying the concrete can be used.

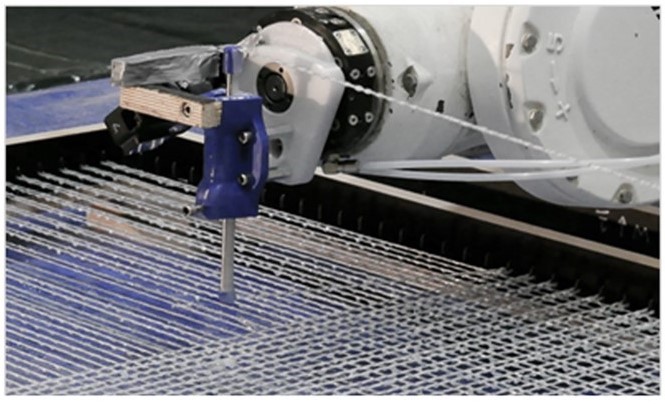

First experiments to produce reinforcement structures by the winding of glass fiber strands have successfully been conducted. Fig. 1 shows the used robot while winding fiber strands around pins on a rectangular frame. The preparation of the fibers occurred in situ with an end-effector, which has been developed for this purpose within this project. After the winding, concrete was applied on the winded frame by shotcreting.

Further investigations on the winding process and the use of different additive manufacturing techniques to apply the concrete are planned for the near future.