Project C 04

Networking with other projects

Poster

TRR277_C04_Poster_1-DFG-BegutachtungTRR277_C04_Poster_2-DFG-Begutachtung

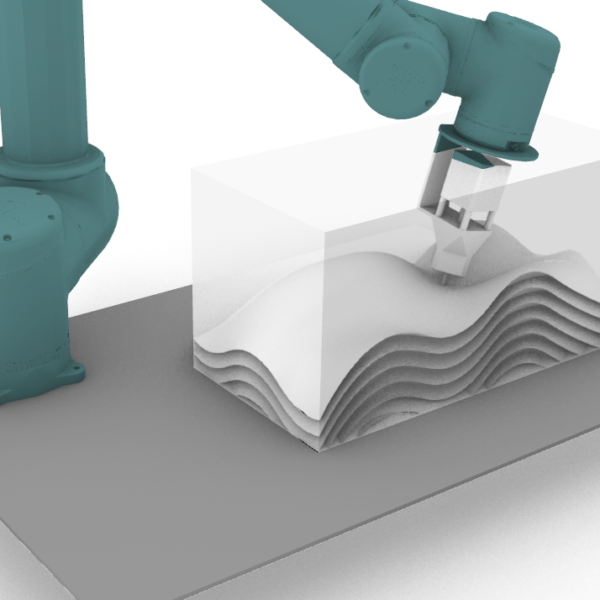

Integrating Digital Design and Additive Manufacturing through BIM-Based Decision Support and Digital Twin Methods

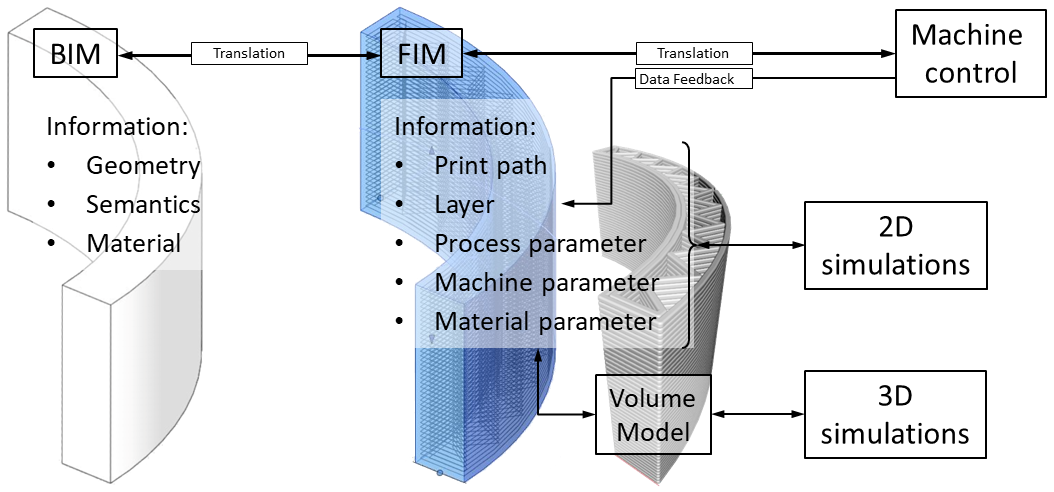

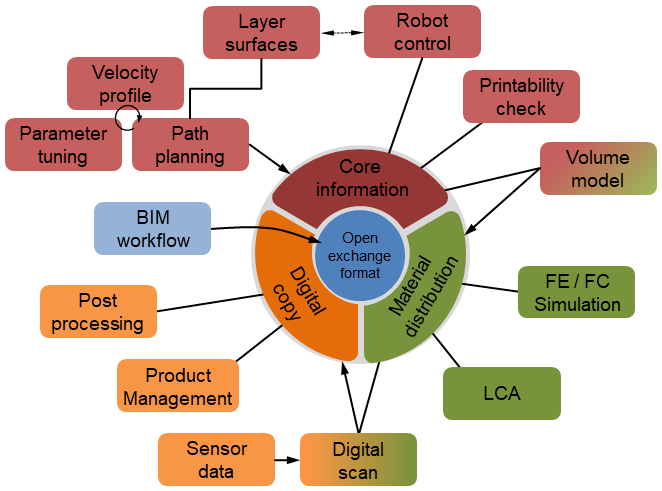

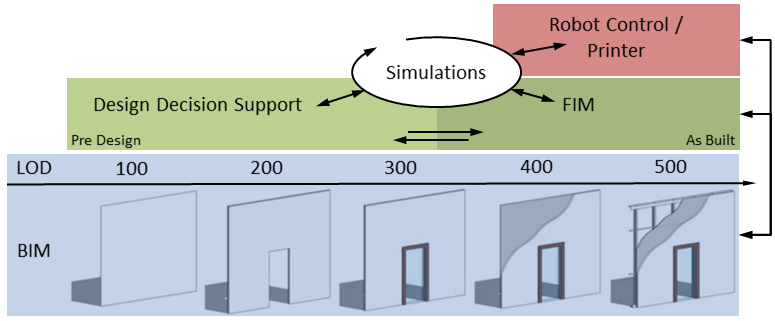

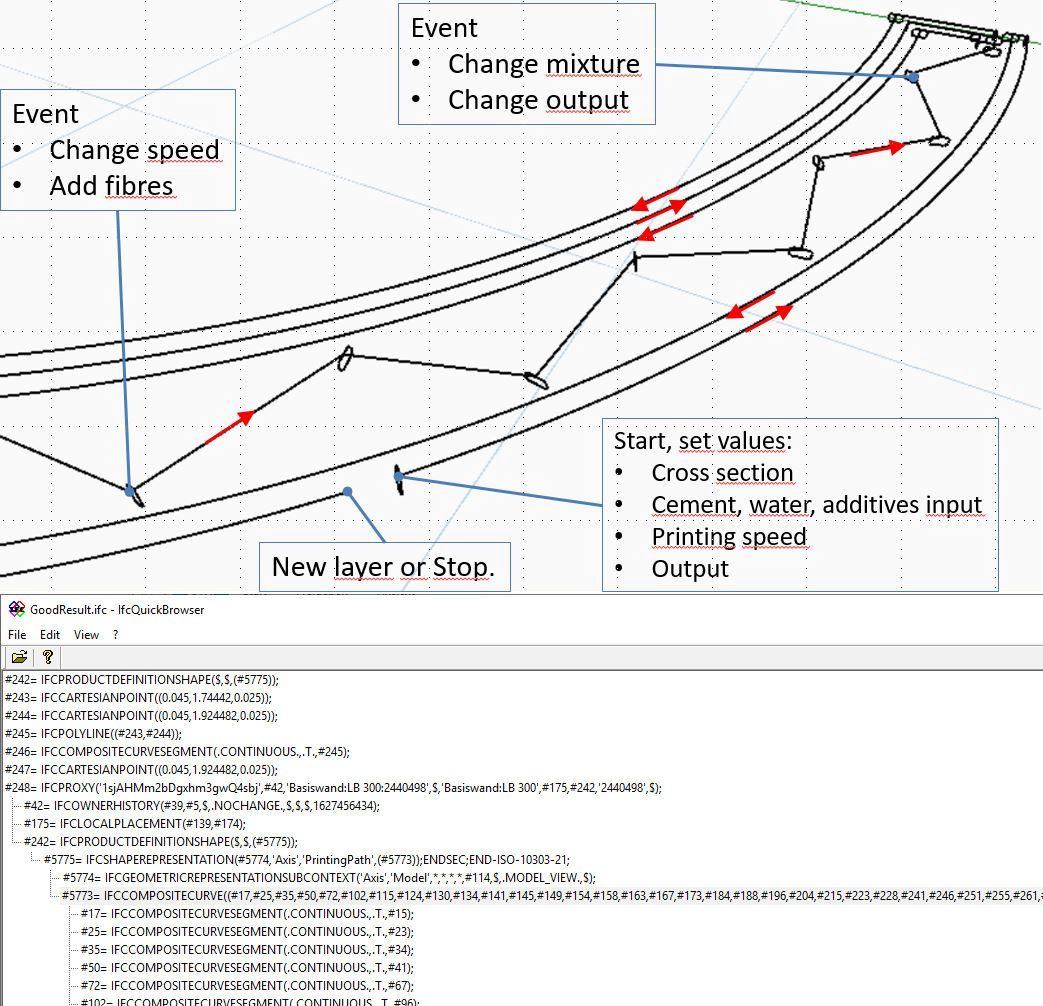

The project contributes to bridging the gap between digital design and additive manufacturing through BIM-based design decision support, modeling of fabrication information and digital twin methods. During early design stages of a BIM-based architectural design, suitable building components and applicable AM methods will be identified through interactive, knowledge-driven processes of decision-making. Methods will be developed for generating Fabrication Information Models (FIM) using Information derived from Building Information Models (BIM). By incorporating manufacturing information from robots and sensors, methods for creating digital twin representations reflecting as-built geometry and properties are developed. The approaches are based on the concept of multi-LOD BIM ensuring the consistency between multiple levels of detail.

Objective

BIM-based Additive Manufacturing: Enabling BIM support for AM methods by design decision support and common data model including digital twin methods

- Develop a Design Decision Support System (DDSS) to support architects making informed decisions about the applicability of AM in the early design phases.

- Develop Fabrication Information Models (FIM) based on Building Information Models for detailed description of AM processes and related fabrication information.

- Integration of Digital Twin methods into FIM to enable the representation of detailed “As-built” information for validation and post-processing purposes.

Methods

Bridge BIM and AM: using the interactive DDSS with formal knowledge, auto-generated FIM based on IFC-Data structure and digital twin methods

- AM knowledge formalization and inquiry using W3C-recommended Semantic Web technologies

- Evaluation of AM methods with Multi-Criteria-Decision-Making (MCDM) methodologies

- IFC-based data structure design for representation of fabrication information and related processes

- Variant modelling for different AM methods based on multi-LOD modelling methods

- Projection of feedback information onto “As-designed” FIM data structures to represent deviations to “As-built” component state

Networking with other projects

During knowledge acquisition, C04 conducts semi-structured interviews with other A and C projects from A01 to A05, and from C01 to C06.

Together with C01 a translation mechanism is developed to enable a direct link between a FIM-Model and their simulation methods.