Project C 01

Bridging Scales – From Geometric Part Details to Construction Elements

Digital models for AM involve many different geometric scales. These scales start from micrometres for metal- or concrete-based processes. AM product scales, which are in the centre of this project, characterise parts as well as entire constructions and range up to tens of meters.

Objective

This project has closely connected central goals: The first one is to develop a consistent description for the relevant geometric models. The second focusses on efficient simulation methods for AM products in construction, based on the multi-scale geometric models. Finally, special emphasis is placed on validation of the developed techniques.

Networking with other projects

Project C01 is directly connected to all three focus areas of the AMC: The process simulation project B01, projects connected to the production technology (A01, A06, A07, and A09) as well as the projects related to the design (C02, C04). We obtain experimental data such as geometric part details and material properties from the A projects and relay their part properties to the design projects. This loop is closed by a continuous verification and validation within C01 as indicated by the circular connection above. We also deliver our findings to C06.

Project leaders

Kollmannsberger, Stefan PD. Dr.-Ing. habil.

is Professor at Bauhaus-University Weimar and is Head of the Chair of Data Science in Civil Engineering. He was head of the work group ‘Simulation in Applied Mechanics’ at the Chair of Computational Modeling and Simulation and has a fifteen year-long scientific record in that field. In this project, he is responsible for the development of simulation methods for metal based artefacts.

Project(s)

Material Modelling and Simulation of Deposition AM Processes on the Part Scale

Bridging Scales – From Geometric Part Details to Construction Elements

Contributors

Christmann, Matti M. Sc.

is a doctoral researcher at the Chair of Data Science in Civil Engineering at Bauhaus-University Weimar. He conducts research on geometric modelling and simulation of additively manufactured (AM) parts, focusing on developing efficient and effective mechanical simulation workflows for evaluating the performance of as-built AM components. His work aims to advance the field of AM by enhancing the re…

Kopp, Philipp Dr.-Ing.

is developing efficient finite element methods for engineering applications at the Chair of Data Science in Civil Engineering of the Bauhaus-Universität Weimar. One of his research areas is the spatiotemporally adaptive resolution and numerical optimization of additive manufacturing processes. He also focusses on immersed simulations of 3D-printed geometries and on spectral element or spectral cel…

Oztoprak, Oguz M. Sc.

Oguz Oztoprak is a doctoral researcher at the Chair of Data Science in Civil Engineering at Bauhaus-University Weimar. He conducts research on geometric modelling and simulation of AM parts. More specificaly, he develops efficient and effective mechanical simulation workflows to integrate complex AM parts into building scale models.

Related Publications

A Plastic Damage Model With Mixed Isotropic–Kinematic Hardening for Low-Cycle Fatigue in 7020 Aluminum2025 | A. Daneshyar, D. Siebert, C. Radlbeck, S. Kollmannsberger: A Plastic Damage Model With Mixed Isotropic–Kinematic Hardening for Low-Cycle Fatigue in 7020 Aluminum Fatigue & Fracture of Engineering Materials & Structures, 2025, https://doi.org/10.1111/ffe.14623.

Data | Zenodo, 2024, https://doi.org/10.5281/zenodo.14223187.

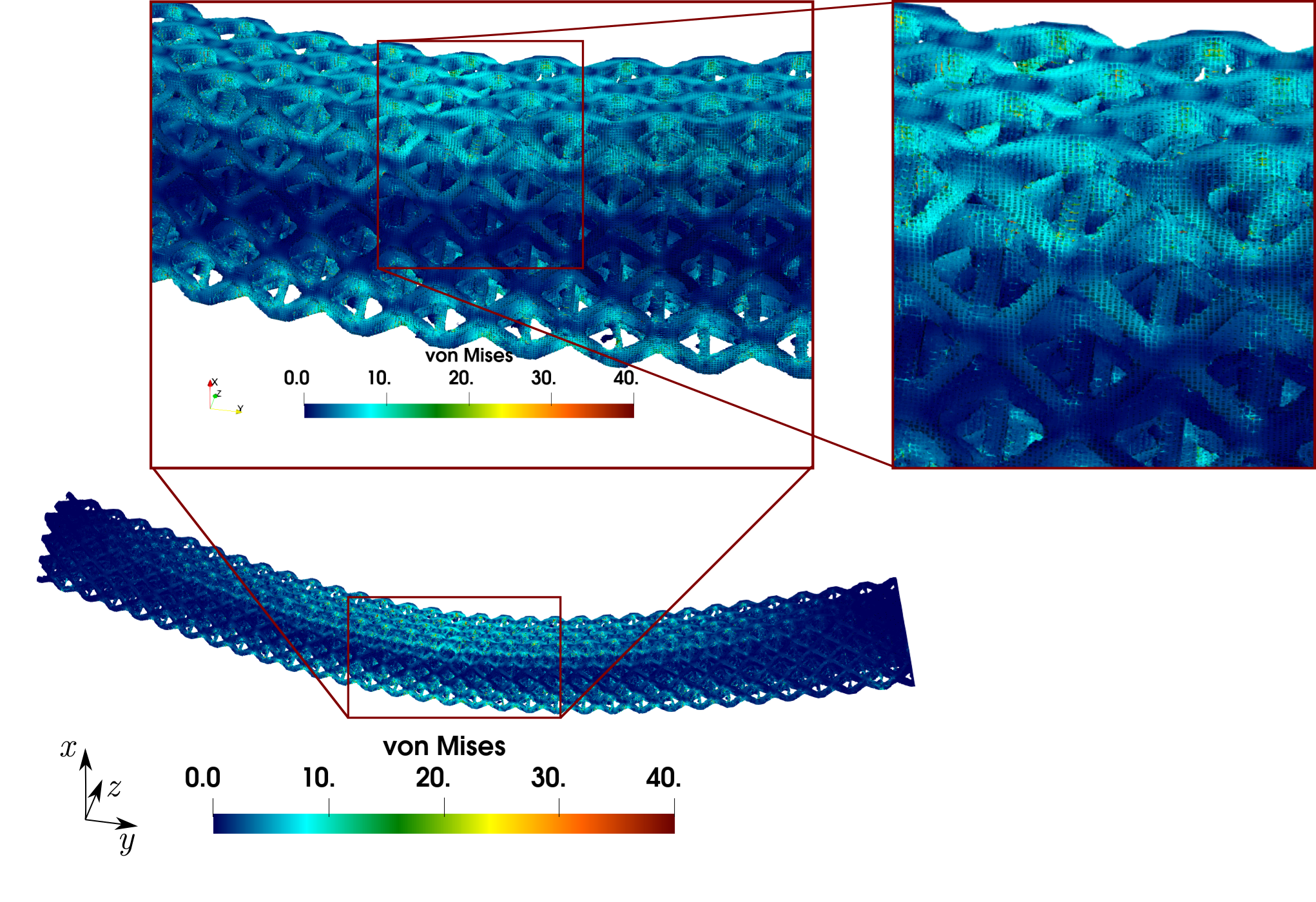

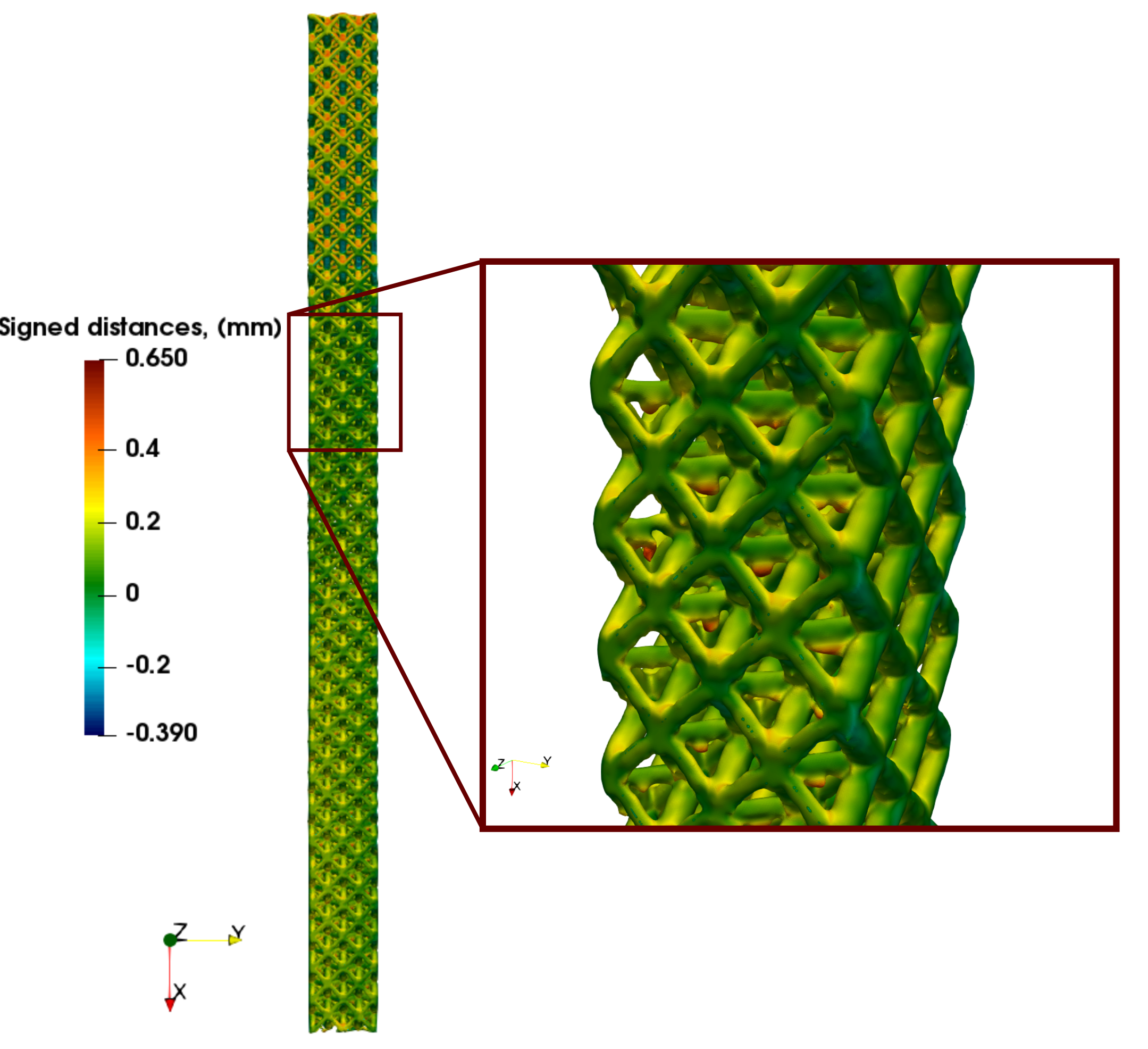

2024 | R. De Biasi, O. Oztoprak, F. Zanini, S. Carmignato, S. Kollmannsberger, M. Benedetti: Predicting fatigue life of additively manufactured lattice structures using the image-based Finite Cell Method and average strain energy density Materials & Design, 2024, https://doi.org/10.1016/j.matdes.2024.113321

Data | Fatigue life prediction of AM lattices based on image-based FCM and average strain energy density dataset, Technische Universität München, 2024, https://doi.org/10.14459/2024mp1751465.

2024 | L. Herrmann, A. Daneshyar, S. Kollmannsberger: The discontinuous strain method: accurately representing fatigue and failure, Computational Mechanics, 2024, https://doi.org/10.1007/s00466-024-02526-9

Data | Zenodo,2024,

https://doi.org/10.5281/zenodo.10215919.

2024 | A. Henkes, L. Herrmann, H. Wessels, S. Kollmannsberger: Generative adversarial networks enable outlier detection and property monitoring for additive manufacturing of complex structures Engineering Applications of Artificial Intelligence, 2024, 108993, https://doi.org/10.1016/j.engappai.2024.108993

Data | Mendeley Data, 2024, https://doi.org/10.17632/zbbrbzrdtd.3.

2024 | M. Meßmer, R. Najian, S. Kollmannsberger, R. Wüchner, K.U. Bletzinger: Shape optimization of embedded solids using implicit Vertex-Morphing, Computer Methods in Applied Mechanics and Engineering, Volume 426, 2024, 116999, ISSN 0045-7825

2024 | C. Faßbender, T. Bürchner, P. Kopp, E. Rank, S. Kollmannsberger: Implicit-explicit time integration for the immersed wave equation. Computers & Mathematics with Applications 163 (2024) 1–13.

https://doi.org/10.1016/j.camwa.2024.02.049

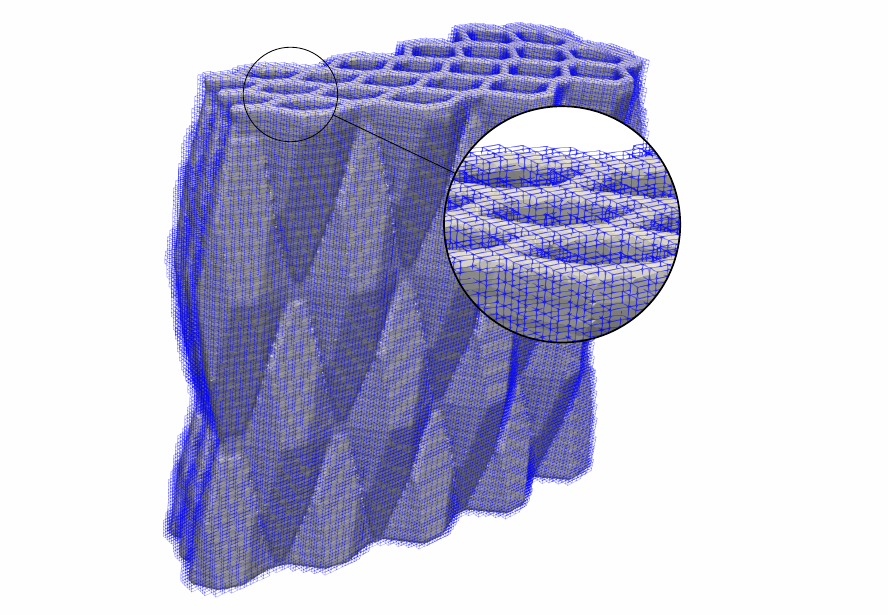

2024 | M. Meßmer, S. Kollmannsberger, R. Wüchner, K.U. Bletzinger: Robust numerical integration of embedded solids described in boundary representation Computer Methods in Applied Mechanics and Engineering, Volume 419, 2024, https://doi.org/10.1016/j.cma.2023.116670.

Data |Quadrature for Embedded Solids – QuESo, GitHub, 2024, https://github.com/manuelmessmer/QuESo.

2023 | Oztoprak, O.; Slepicka, M.; Aninger, A.L.; Kollmannsberger, S.; Rank, E.; Borrmann, A.: Linking Fabrication Information Modeling and Finite Cell Method for simulating the behavior of additively manufactured building components. In: EG-ICE Conference, 2023.

2023 | A. Daneshyar, L. Herrmann, S. Kollmannsberger: From ductile damage to unilateral contact via a point-wise implicit discontinuity. In: Computational Mechanics, 2023, Sep.

doi: 10.1007/s00466-023-02392-x

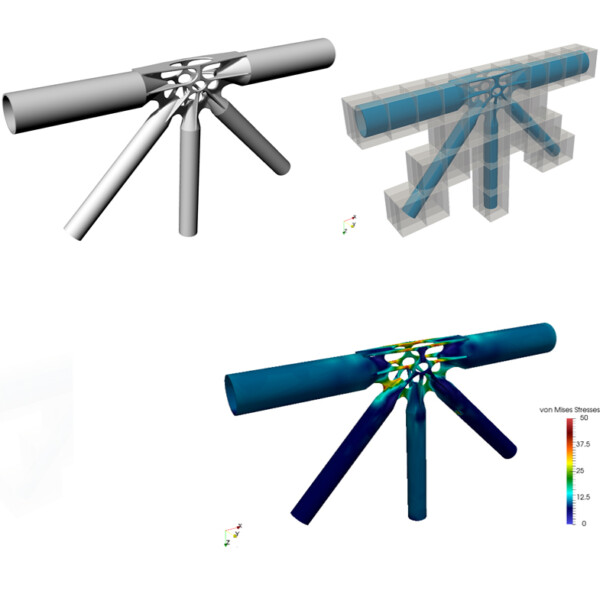

2023 | O. Oztoprak, A. Paolini, P. D’Acunto, E. Rank, S. Kollmannsberger: Two-scale analysis of spaceframes with complex additive manufactured nodes. In: Engineering Structures, vol. 289, p. 116283, Aug. 2023,

doi: 10.1016/j.engstruct.2023.116283

2022 | D’Angella, D., Kollmannsberger, S., Reali, A., Rank, E., Hughes, T. J. R.: An accurate strategy for computing reaction forces and fluxes on trimmed locally refined meshes. In: Journal of Mechanics, vol. 38, pp. 60–76, Apr. 2022

http://doi: 10.1093/jom/ufac006

2021 | Alaimo, G.; Carraturo, M.; Korshunova, N.; Kollmannsberger, S.: Numerical evaluation of high cycle fatigue life for additively manufactured stainless steel 316L lattice structures. In: Material Design and Processing Communication 3 (4), pp. e249, Wiley, 2021. – DOI: 10.1002/mdp2.249.

2021 | Jomo, J.; Oztoprak, O.; de Prenter, F.; Zander, N.; Kollmannsberger, S.; Rank, E.: Hierarchical multigrid approaches for the finite cell method on uniform and multi-level hp-refined grids. In: Computer Methods in Applied Mechanics and Engineering 386, pp. 114075, 2021. – DOI: 10.1016/j.cma.2021.114075.

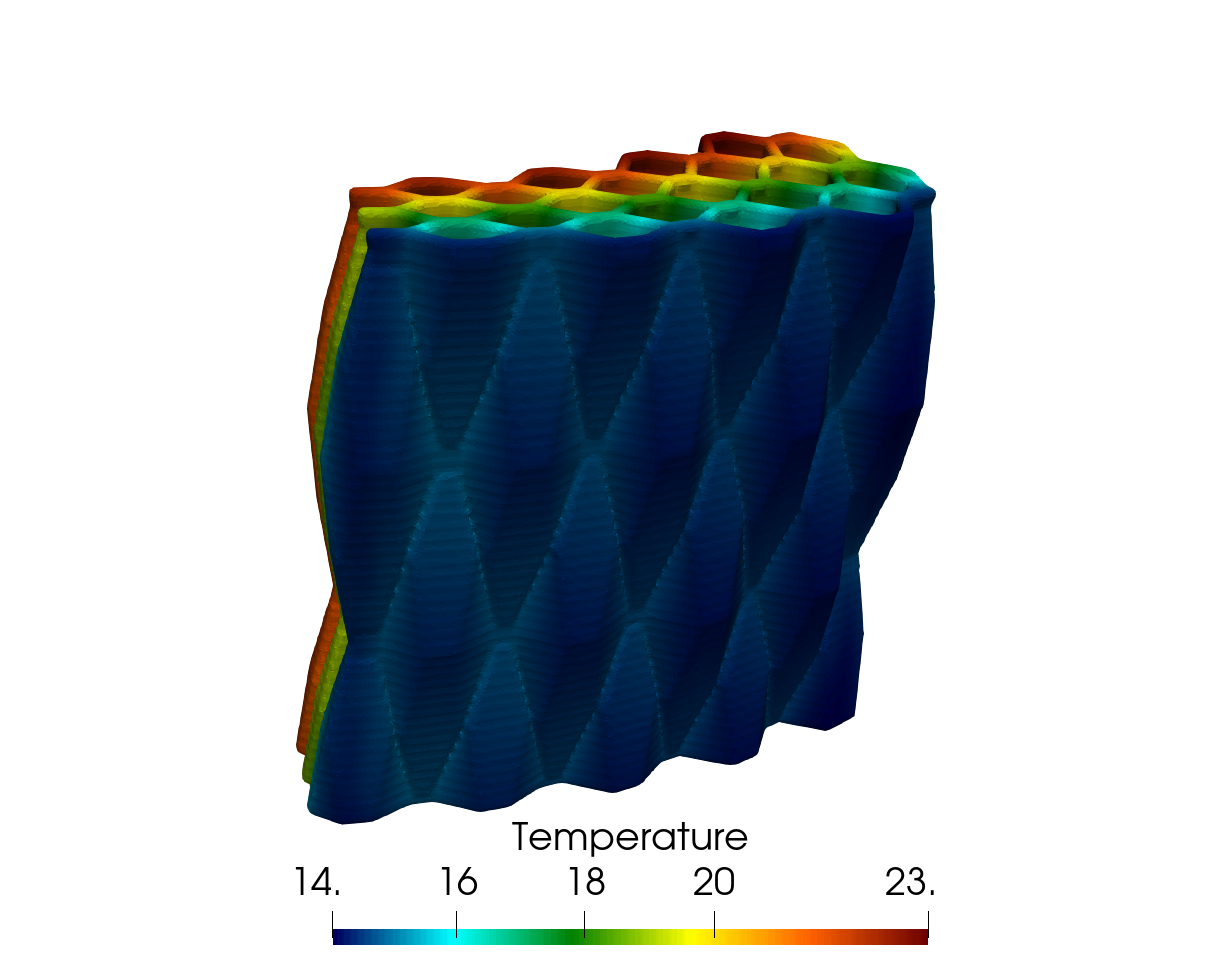

2021 | Paolini, A.; Korshunova, N.; Kollmannsberger, S.; Rank, E.: Multiscale analysis of high damping composites using the finite cell and the mortar method. In: International Journal of Structural Stability and Dynamics, 2021. – DOI: 10.1142/S0219455421501492.

2021 | Korshunova, N.; Papaioannou, I.; Kollmannsberger S.; Straub, D.; Rank, E.: Uncertainty quantification of microstructure variability and mechanical behavior of additively manufactured lattice structures. In: Computer Methods in Applied Mechanics and Engineering 385 (1), pp. 114049, 2021. – DOI: https://doi.org/10.1016/j.cma.2021.114049.

2021 | Korshunova, N.; Alaimo, G.; Hosseini, S. B.; Carraturo, M.; Reali, A.; Niiranen, J.; Auricchio, F.; Rank, E.; Kollmannsberger, S.: Bending behavior of octet-truss lattice structures: modelling options, numerical characterization and experimental validation. In: Materials & Design, 2021.

2021 | Korshunova, N.; Alaimo, G.; Hosseini, S.; Carraturo, M.; Reali, A.; Niiranen, J.; Auricchio, F.; Rank, E.; Kollmannsberger, S.: A CT-based numerical characterization of tensile behavior of additively manufactured octet-truss structures and its experimental validation. In: Additive Manufacturing, p. 101949, 2021. – DOI: https://doi.org/10.1016/j.addma.2021.101949.

2020 | Wassermann, B.; Korshunova, N.; Kollmannsberger, S.; Rank, E.; Elber, G.: Finite Cell Method for functionally graded materials based on V-models and homogenized microstructures. In: Advanced Modeling and Simulation in Engineering Sciences (7), pp. 49, 2020. – DOI: 10.1186/s40323-020-00182-1.

More projects of

Focus Area C

3D Structural Puzzle – Numerical Multi Scale Shape and Topology Optimisation Methods to Additively Manufacture Optimal Structures from Optimised Pieces

Integration of Passive and Active Functions in Additively Manufactured Construction Elements

Integrating Digital Design and Additive Manufacturing through BIM-Based Decision Support and Digital Twin Methods

Jointing Principles for Combination of Concrete Elements Produced by Different Additive Manufacturing Processes

Integration of Additive Manufacturing in the Construction Process

Environmental Life Cycle Assessment – Determination of Ecological Sustainability Potentials by AMC