Project A 01

![]()

Approach

Visuals

Networking with other projects

Poster

TRR277_A01_Poster_1-DFG-Begutachtung

TRR277_A01_Poster_2-DFG-Begutachtung

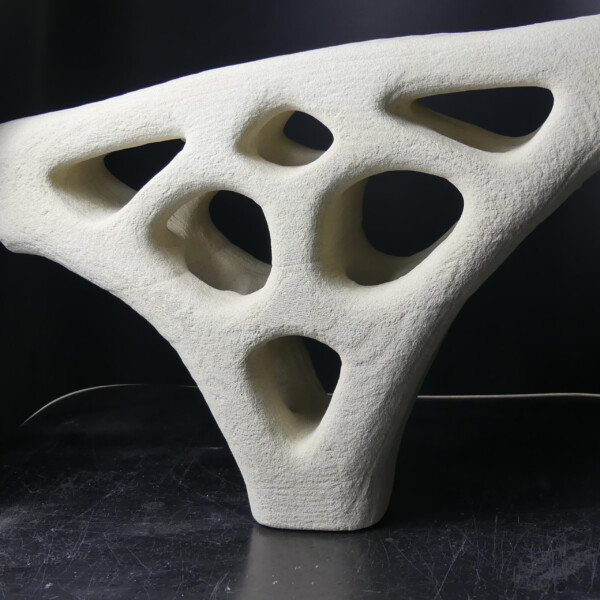

Particle-Bed 3D Printing by Selective Cement Activation (SCA) – Sustainability, process enhancement and material models

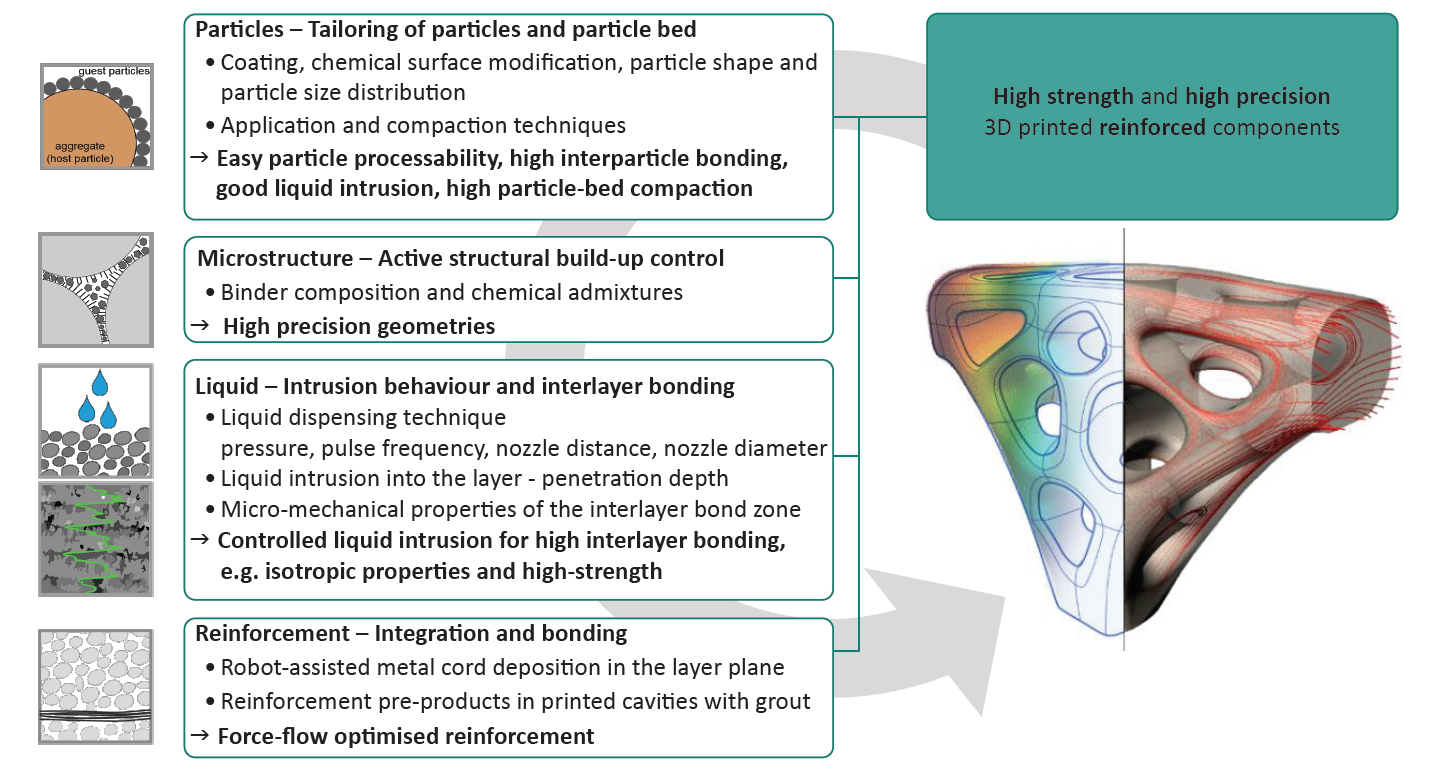

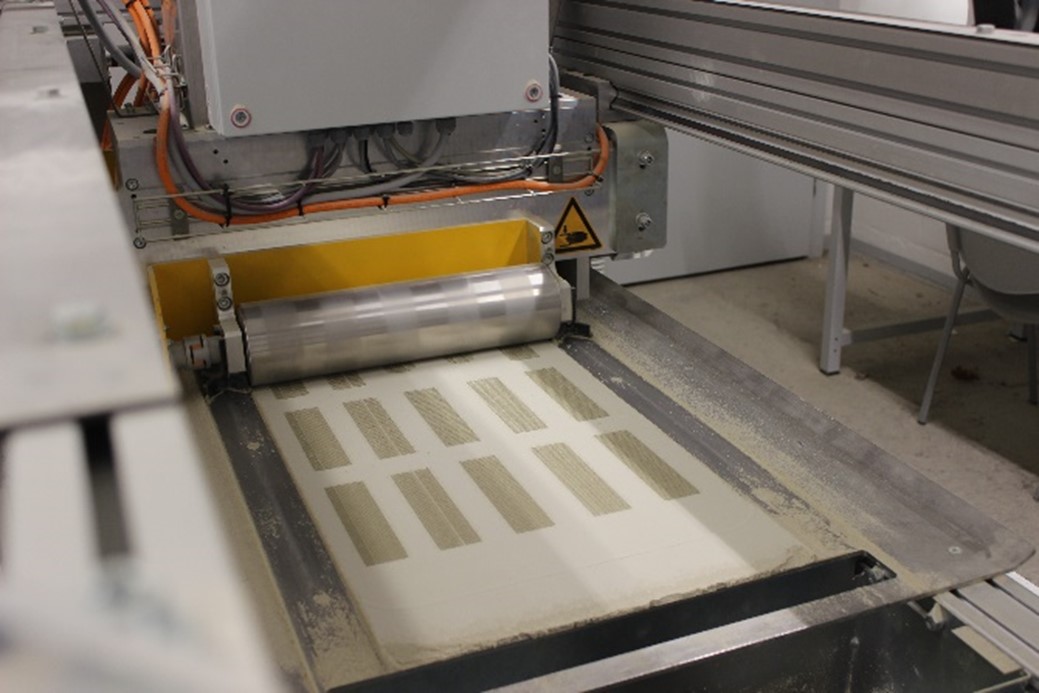

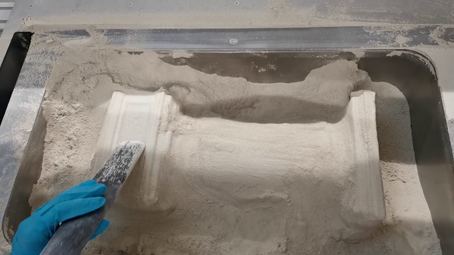

The focus of this project is on particle-bed 3D printing (PB3DP) by Selective Cement Activation (SCA) with the aim to gain a fundamental understanding of the involved material-process interactions. In SCA a liquid is selectively applied on a dry particle-bed, consisting of fine aggregates and cement, so that the hydration reaction of the cement and thus the hardening only occurs locally. This process allows in particular the manufacturing of free formed elements with almost no restrictions in shape and topology.

Aim

The goal of this project is a fundamental understanding of the material-process interactions in particle-bed 3D printing by Selective Cement Activation. This is necessary to tailor both the material and the process to obtain the desired component properties.

Networking with other projects

TThe collaborations will specifically address the following aspects: The usage of RC material for SCA printing (A02), reinforcement integration (A05), computational modelling of the fluid intrusion into the particle-bed (B03), fracture analysis of hardened-state material (C01), shape optimisation of 3D printed elements (C02), sharing expert knowledge about SCA (C04), jointing principles (C05) and the evaluation of the ecological footprint of SCA printing (C09)

Project leaders

Kwade, Arno Prof. Dr.-Ing.

Head of the institute for particle technology. Head of iPAT and supports the academic staff regarding the conditioning of particle products.

Project(s)

Particle-Bed 3D Printing by Selective Cement Activation (SCA) – Sustainability, process enhancement and material models

Particle-Bed 3D Printing by Selective Cement Paste Intrusion (SPI) – Particle Surface Functionalisation, Particle Synthesis and Integration of WAAM Reinforcement

Lowke, Dirk Prof. Dr.-Ing.

Prof. Dr.-Ing. Dirk Lowke is Chair of Materials and Methods in Digital Construction. He will advise the scientific staff in carrying out their work in line with the formulated project aims. He is responsible for the coordination and quality control of all work conducted by the Chair of Materials and Methods in Digital Construction at the Department of Materials Engineering at TU Munich.

Project(s)

Particle-Bed 3D Printing by Selective Cement Activation (SCA) – Sustainability, process enhancement and material models

Integrated Additive Manufacturing Processes for Reinforced Shotcrete 3D Printing (SC3DP) Elements with Precise Surface Quality

Contributors

Dorresteijn, Evelien M. Sc.

is a researcher at Institute of Building Materials, Concrete Construction and Fire Safety and works for the project A01.

Project(s)

Particle-Bed 3D Printing by Selective Cement Activation (SCA) – Sustainability, process enhancement and material models

Herding, Friedrich M. Sc.

M. Sc. Friedrich Herding is a research associate in the working group of Prof. Dr.-Ing. Dirk Lowke. He is researching the material-process interaction in the SCA process.

Project(s)

Particle-Bed 3D Printing by Selective Cement Activation (SCA) – Sustainability, process enhancement and material models

Meier, Niklas M. Sc.

is a research associate in the work group of Prof. Dr.-Ing. Arno Kwade. He is responsible for the development of tailored particles for the SCA process.

Project(s)

Particle-Bed 3D Printing by Selective Cement Activation (SCA) – Sustainability, process enhancement and material models

Zetzener, Harald Dr.-Ing.

deputy director of the institute for particle technology, head of Division Powder and Slurry Processes, supports Prof. Kwade in leading the project.

Project(s)

Particle-Bed 3D Printing by Selective Cement Activation (SCA) – Sustainability, process enhancement and material models

Particle-Bed 3D Printing by Selective Cement Paste Intrusion (SPI) – Particle Surface Functionalisation, Particle Synthesis and Integration of WAAM Reinforcement

Related Publications

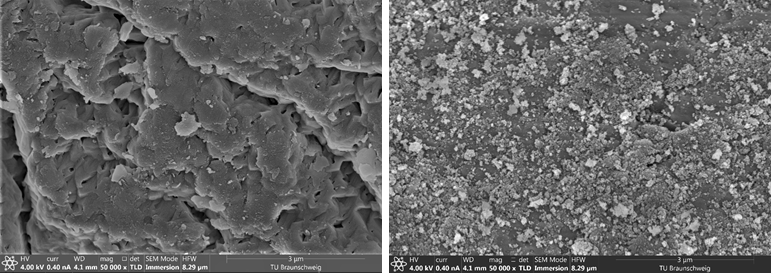

Surface modification of bulk material for particle bed 3D concrete printing – Effect on wettability, porosity, and mechanical properties2025 | N. Meier, F. Herding, H. Zetzener, I. Mai, D. Lowke, A. Kwade: Surface modification of bulk material for particle bed 3D concrete printing – Effect on wettability, porosity, and mechanical properties Advanced Powder Technology, 2025, https://doi.org/10.1016/j.apt.2025.105123

Data |Zenodo, 2025, https://doi.org/10.5281/zenodo.17641009

2024 |F. Herding, D. Lowke: Improving the Dimensional Accuracy in Selective Cement Activation by w/c-Ratio Gradation Fourth RILEM International Conference on Concrete and Digital Fabrication, 2024, https://doi.org/10.1007/978-3-031-70031-6_43

2024 |J. Fleckenstein, B. Knychalla, D. Briels, A. Baghdadi, G. Placzek, F. Herding, P. Schwerdtner, T. Auer, D. Lowke, H. Kloft, K. Dörfler, P. Ayres, M. Thomson , R. Sheil, M. Skavara: BREUER X AM: FUNCTIONAL HYBRIDISATION IN CONCRETE BUILDING ENVELOPE ELEMENTS THROUGH ADDITIVE MANUFACTURING Fabricate 2024: Creating Resourceful Futures, 2024, https://doi.org/10.2307/jj.11374766.29

2024 |F. Herding, D. Lowke: Improving the dimensional accuracy in selective cement activation by w/c-ratio gradation, Fourth RILEM International Conference on Concrete and Digital Fabrication Munich, RILEM Bookseries, vol 53, Springer, https://doi.org/10.1007/978-3-031-70031-6_43

2024 |J. Fleckenstein, B. Knychalla, D. Briels, A. Baghdadi, G. Placzek, F. Herding, P. Schwerdtner, T. Auer, D. Lowke, H. Kloft, K. Dörfler, P. Ayres, M. R. Thomsen, B. Sheil, M. Skavara: BREUER X AM: Functional hybridisation in concrete building envelope elements through additive manufacturing, Fabricate 2024: Creating Resourceful Futures, UCL Press, 2024, 196–205, https://doi.org/10.2307/jj.11374766.29

2024 | J. Hitzegrad, L. Brohmann, F. Herding, K. Pfennings, S. Jonischkies, E. Scharnbeck, J. Mainka, I. Mai, C. Windt, H. Kloft, A. Wehrmann, D. Lowke, N. Goseberg: Surfaces of coastal biogenic structures: exploiting advanced digital design and fabrication strategies for the manufacturing of oyster reef and mussel bed surrogates, Front. Mar. Sci., 11:1395025, 2024, https://doi.org/10.3389/fmars.2024.1395025

2023 | F. Herding, A. Strasser, D. Briels, D. Lowke, T. Kränkel: Experimental results for mechanical and thermal properties of SCA material, Dataset, TUM: Munich, 2023, https://doi.org/10.14459/2023mp1720074

2023 | F. Herding, I. Mai, D. Lowke: Reduction of the cement content in Selective Cement Activation. In: ibausil 2023

https://doi.org/10.1002/cepa.2826

2023 | F. Herding, I. Mai, D. Lowke: Effect of Grain Size and Layer Thickness on Hardened State Properties in Selective Cement Activation. In: ibausil 2023

https://doi.org/10.1002/cepa.2816

2023 | D. Talke, B. Saile, N. Meier, F. Herding, I. Mai, H. Zetzener, A. Kwade, D. Lowke: Particle-bed 3D printing by selective cement activation – Influence of process parameters on particle-bed density. In: Cement and Concrete Research, 168. (2023)

https://doi.org/10.1016/j.cemconres.2023.107140

2022 | Böhler, D., Mai, I., Freund, N., Lachmayer, L., Raatz, A., Lowke, D.: Influence of Material and Process Parameters on Hardened State Properties of Shotcrete 3D-Printed Elements. In: Buswell, R., Blanco, A., Cavalaro, S., Kinnell, P. (eds) Third RILEM International Conference on Concrete and Digital Fabrication. DC 2022. RILEM Bookseries, vol 37. Springer, Cham.

https://doi.org/10.1007/978-3-031-06116-5_38

2022 | Herding, F., Mai, I., Lowke, D.: Effect of Curing in Selective Cement Activation. In: Buswell, R., Blanco, A., Cavalaro, S., Kinnell, P. (eds) Third RILEM International Conference on Concrete and Digital Fabrication. DC 2022. RILEM Bookseries, vol 37. Springer, Cham.

https://doi.org/10.1007/978-3-031-06116-5_42

2022 | Mai, I.; Lowke, D.; Perrot, A.: Fluid intrusion in powder beds for selective cement activation – an experimental and analytical study. In: Cement and Concrete Research, CCR 156 (106771), 2022

https://doi.org/10.1016/j.cemconres.2022.106771

2022 | Lowke, D.; Mai, I.; Keita, E.; Perrot, A.; Weger, D.; Gehlen, C.; Herding, F.; Zuo, Wenqiang; Roussel, N.: Material-process interactions in particle bed 3D printing and the underlying physics. In: Cement and Concrete Research, CCR 156 (106748), 2022

https://doi.org/10.1016/j.cemconres.2022.106748

2022 | Mai, I., Herding, F., Lowke, D.: Evaluating the Effect of Methyl Cellulose on Hardened State Properties in Selective Cement Activation. In: Buswell, R., Blanco, A., Cavalaro, S., Kinnell, P. (eds) Third RILEM International Conference on Concrete and Digital Fabrication. DC 2022. RILEM Bookseries, vol 37. Springer, Cham.

https://doi.org/10.1007/978-3-031-06116-5_43

2022 |Lowke, D.; Mai, I.; Keita, E.; Perrot, A.; Weger, D,; Gehlen, C.; Herding, F.; Zuo, W.; Roussel, N.: Material-process interactions in particle bed 3D printing and the underlying physics, In: Cement and Concrete Research, Volume 156, June 2022, 106748, DOI: http//:doi.org/10.1016/j.cemconres.2022.106748

2022 |Lowke, D.; Mai, I.; Perrot, A.: Fluid intrusion in powder beds for selective cement activation – An experimental and analytical study, In: Cement and Concrete Research, Volume 156, June 2022, 106748, DOI: http//:doi.org/10.1016/j.cemconres.2022.106771

2020 | Lowke, D.; Talke, D.; Dreßler, I.; Weger, D.; Gehlen, C.; Ostertag, C.; Rael, R.: Particle bed 3D printing by selective cement activation – Applications, material and process technology. In: Cement and Concrete Research 134,2020. – DOI: https://doi.org/10.1016/j.cemconres.2020.106077.

More projects of

Focus Area A

Particle-Bed 3D Printing by Selective Cement Paste Intrusion (SPI) – Particle Surface Functionalisation, Particle Synthesis and Integration of WAAM Reinforcement

Extrusion of Near-Nozzle Mixed Concrete –Individually Graded in Density and in Rate of 3D Fibre Reinforcement

Integrated Additive Manufacturing Processes for Reinforced Shotcrete 3D Printing (SC3DP) Elements with Precise Surface Quality

Integration of Individualized Prefabricated Fibre Reinforcement in Additive Manufacturing with Concrete

Laser Powder-Bed Fusion (LPBF) of Steel Elements for Construction – Basics of Design and Mechanical Resilience.

Wire and Arc Additive Manufacturing (WAAM) of Complex Individualized Steel Components

Structural Timber by Individual Layer Fabrication (ILF)

Injection 3D Concrete Printing (I3DCP) – Material Efficient Lightweight Reinforced Concrete Structures Based on Spatially Complex Strut-and-Tie-Models

Earth Additive Manufacturing (EAM) – Material and Process Combinations for AM with Earth-based Materials