Research Summary Report

Research Summary Report of C02

Category: Research Summary Report

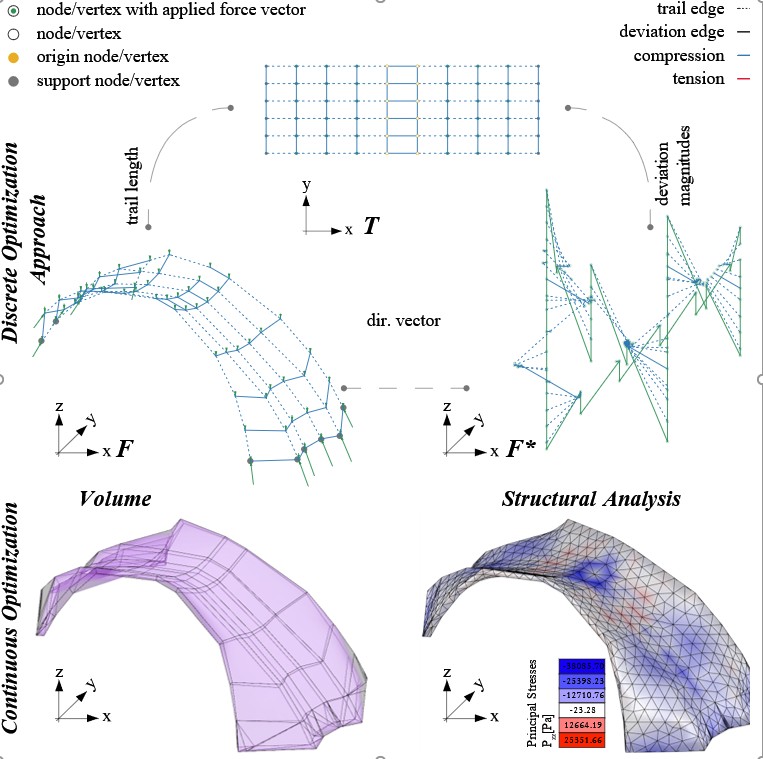

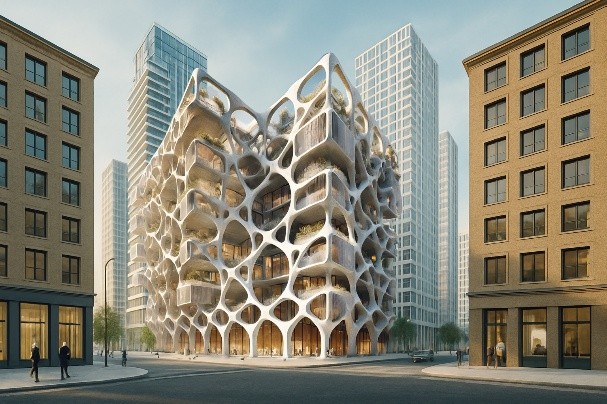

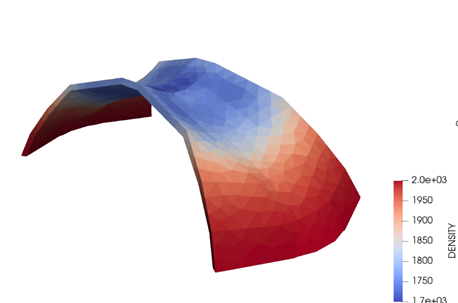

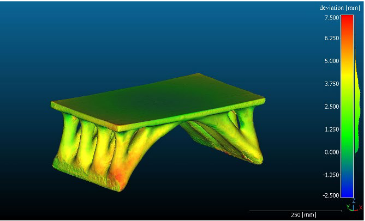

3D Structural Puzzle – Numerical Multi Scale Shape and Topology Optimisation Methods to Additively Manufacture Optimal Structures from Optimised Pieces [19.12.2025] Richter, Christiane; Researcher, christiane.richter@tum.de Prof. Dr. D`Acunto, Pierluigi; Project leader, pierluigi.dacunto@tum.de TUM, Professorship of Structural Design (SD) Main Goal Current building practices often adopt a sequential design approach, where architectural, structural, and fabrication aspects are addressed independently, resulting in excessive material consumption. The CO2 project aims to establish a Holistic Design Framework integrating the above-mentioned aspects. Within this framework, additive manufacturing facilitates structural optimization by enabling the production of bespoke geometries for an effective use of material resources. …

Research Summary Report of B04

Category: Research Summary Report

Process Control and Adaptive Path Planning for Additive Manufacturing Processes Based on Industrial Robots with an Extended Degree of Freedom [18.12.2025] Heeren, Hauke; Researcher,heeren@match.uni-hannover.de Lachmayer, Lukas; Resarcher, lachmayer@match.uni-hannover.de Prof. Dr. Annika Raatz; Project leader, raatz@match.uni-hannover.de LUH, Institute of Assembly Technology and Robotics Main Goal The research of project B04 is dedicated to extending the current state-of-the-art trajectory planning and process control algorithms for concrete-based additive manufacturing. The objective is to enable reproducible production of multi-material components utilizing mobile robot systems in motion, known as Print-While-Drive. Achieving this requires …

Research Summary Report of A04

Category: Research Summary Report

Integrated Additive Manufacturing Processes for Reinforced Shotcrete 3D Printing (SC3DP) Elements with Precise Surface Quality [17.12.2025] Dörrie, Robin; Researcher, r.doerrie@tu-braunschweig.de Prof. Dr. Harald Kloft; Project leader, kloft@tu-braunschweig.de Technische Universität Braunschweig; ITE Institute of Structural Design Main Goal The project aims to fundamentally understand the Shotcrete 3D Printing (SC3DP) technology to manufacture sustainable, multi-objective optimised, reinforced concrete components with precise surface quality and improved building physics via functional integration. It seeks to minimise the carbon footprint of 3D printed structures by exploring various material strategies, such as reducing cement content by increasing the aggregate size or replacing cement with a …

Research Summary Report of A10

Category: Research Summary Report

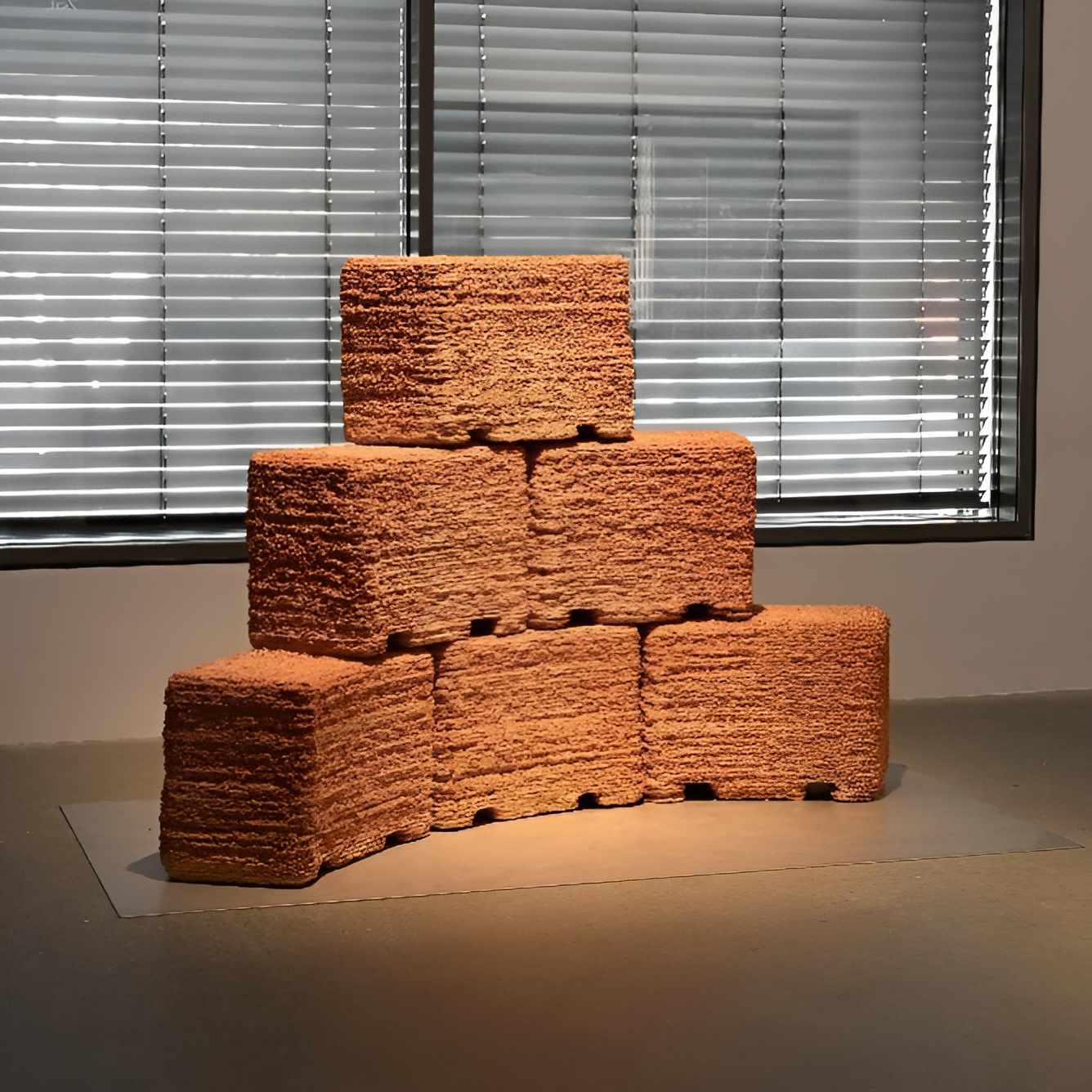

Earth Additive Manufacturing (EAM) – Material and Process Combinations for AM with Earth-based Materials [31.10.2025] Krakovská, Ema; Researcher, ema.krakovska@tum.de Prof. Dr. Kathrin Dörfler; Project leader, doerfler@tum.de Technical University of Munich, Professorship of Digital Fabrication Main Goal The primary research objective of A10 is to conceive and investigate two novel Earth Additive Manufacturing (EAM) processes, their material-process interactions, and their evaluation in large-scale architectural applications. Focusing on the characterisation of earth-based material mixtures (PL Machner), the project investigates a) Sprayed Earth Additive Manufacturing (SEAM) as a deposition-based process (PL Kloft) and b) Intrusion Earth Additive Manufacturing (IEAM) as a particle-bed-based …

Research Summary Report of B04

Category: Research Summary Report

Process Control and Adaptive Path Planning for Additive Manufacturing Processes Based on Industrial – Robots with an Extended Degree of Freedom [07.11.2025] Akica, Ilknur; Researcher, i.akica@tu-braunschweig.de Hürkamp, André; Project leader, a.huerkamp@tu-braunschweig.de TU Braunschweig, Institute of Machine Tools and Production Technology (IWF) Main Goal The integration of robot-guided additive manufacturing in the construction industry increases the degree of automation and can thus lead to an increased productivity and increased component quality. In shotcrete 3D printing (SC3DP), reproducible manufacturing results and ensuring component quality are major challenges, as the properties of shotcrete depend on many different parameters (e.g. temperature, pressure, water-cement ratio, hardening accelerator). The goal of this …

Research Summary Report of C09

Category: Research Summary Report

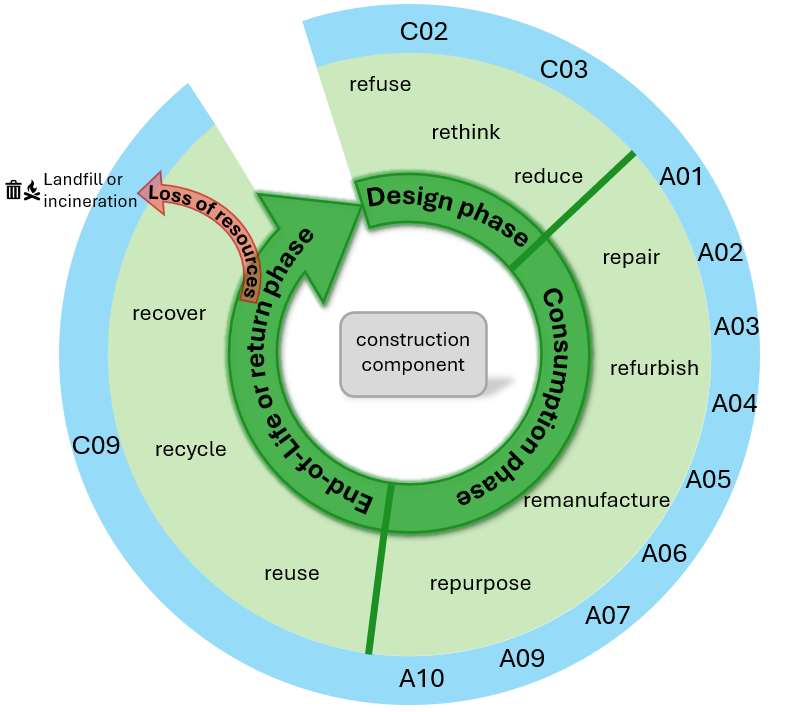

Environmental Life Cycle Assessment – Determination of Ecological Sustainability Potentials by AMC [07.11.2025] Albrecht, Sophie Viktoria; Researcher, sophie.albrecht@oth-regensburg.de Thiel, Charlotte; Project leader, charlotte.thiel@oth-regensburg.de OTH Regensburg, Construction Materials Main Goal C09 aims to enhance the ecological sustainability of Additive Manufacturing in Construction (AMC) by quantifying and optimizing its environmental benefits through comprehensive Life Cycle Assessments (E-LCA) from cradle to cradle. This involves developing transparent Product Environmental Footprint Category Rules (PEFCR), identifying impactful reduction measures, and integrating circular design strategies to create durable, efficient, and reusable components. C09 enables early-stage, sustainability-focused decision-making, fostering material-efficient, low-impact construction practices and reducing the environmental footprint of the building sector. Summary …

Research Summary Report of C02

Category: Research Summary Report

3D Structural Puzzle – Numerical Multi Scale Shape and Topology Optimisation Methods to Additively Manufacture Optimal Structures from Optimised Piecest [28.10.2025] Jakobs, Philipp; Researcher, philipp.jakobs@tum.de Wüchner, Roland; Project leader, wuechner@tum.de TUM, Chair of Structural Analysis Main Goal Current building practices often adopt a sequential design approach, where architectural, structural, and fabrication aspects are addressed independently, resulting in excessive material consumption. The CO2 project aims to establish a Holistic Design Framework (HDF) integrating the above-mentioned aspects. Within this framework, additive manufacturing facilitates structural optimization by enabling the production of bespoke geometries for an effective use of material resources. Departing from the conventional sequential approach, the HDF concurrently …

Research Summary Report of A02

Category: Research Summary Report

Particle-Bed 3D Printing by Selective Cement Paste Intrusion (SPI) – Particle Surface Functionalisation, Particle Synthesis and Integration of WAAM Reinforcement [22.10.2025] Straßer, Alexander; Researcher, alexander.strasser@tum.de Kränkel, Thomas; Researcher thomas.kraenkel@tum.de Gehlen, Christoph; Project leader, gehlen@tum.de TUM, Chair of Materials Science and Testing Main Goal The goal of A02 is to implement reinforcement by Wire and Arc Additive Manufacturing (WAAM) in concrete elements produced by Selective Paste Intrusion (SPI), see Figure 1. The SPI and combined SPI + WAAM process will also be further investigated with a focus on ecological improvements. …

Research Summary Report of B03

Category: Research Summary Report

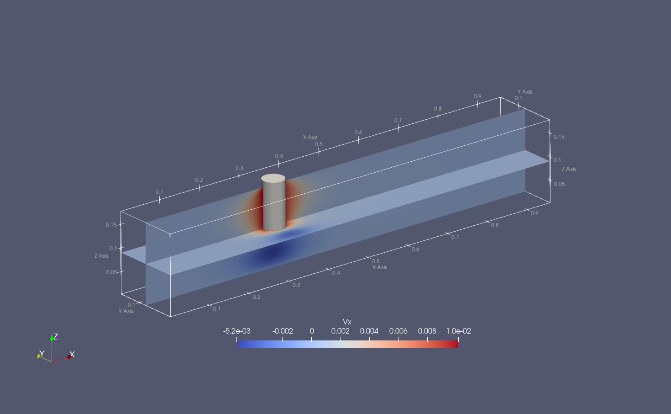

Modelling and Simulation of Concrete 3D Printing Based on a Massively Parallel Multi-Phase, Multi-Component LBM Approach [19.10.2025] Kutscher, Konstantin; Researcher, kutscher@irmb.tu-bs.de Geier, Markus; Project leader,geier@irmb.tu-bs.de Krafczyk, Manfred; Project leader, kraft@irmb.tu-bs.de TU Braunschweig, IRMB Main Goal The project is currently concerned with the simulation of a moving nozzle for the injection process using I3DCP. We are particularly interested in the influence of the movement of the nozzle on the printed strand. Summary In order to avoid costly remeshing of the moving nozzle in the simulation of Injection 3D Concrete Printing …

Research Summary Report of A01

Category: Research Summary Report

Particle-Bed 3D Printing by Selective Cement Activation (SCA) – Sustainability, process enhancement and material models [14.10.2025] Herding, Friedrich; Researcher, friedrich.herding@tum.de Lowke, Dirk; Project leader, lowke@tum.de Technical University of Munich, Chair of Materials and Methods in Digital Construction Main Goal Our primary research goal is to develop a comprehensive understanding of the interactions between material and process in Particle Bed 3D Printing (PB3DP) using Selective Cement Activation (SCA). This knowledge will enable us to fabricate concrete elements with high mechanical strength and dimensional accuracy. We are also examining various strategies for reinforcement integration, which are essential for producing load-bearing …

Research Summary Report of A04

Category: Research Summary Report

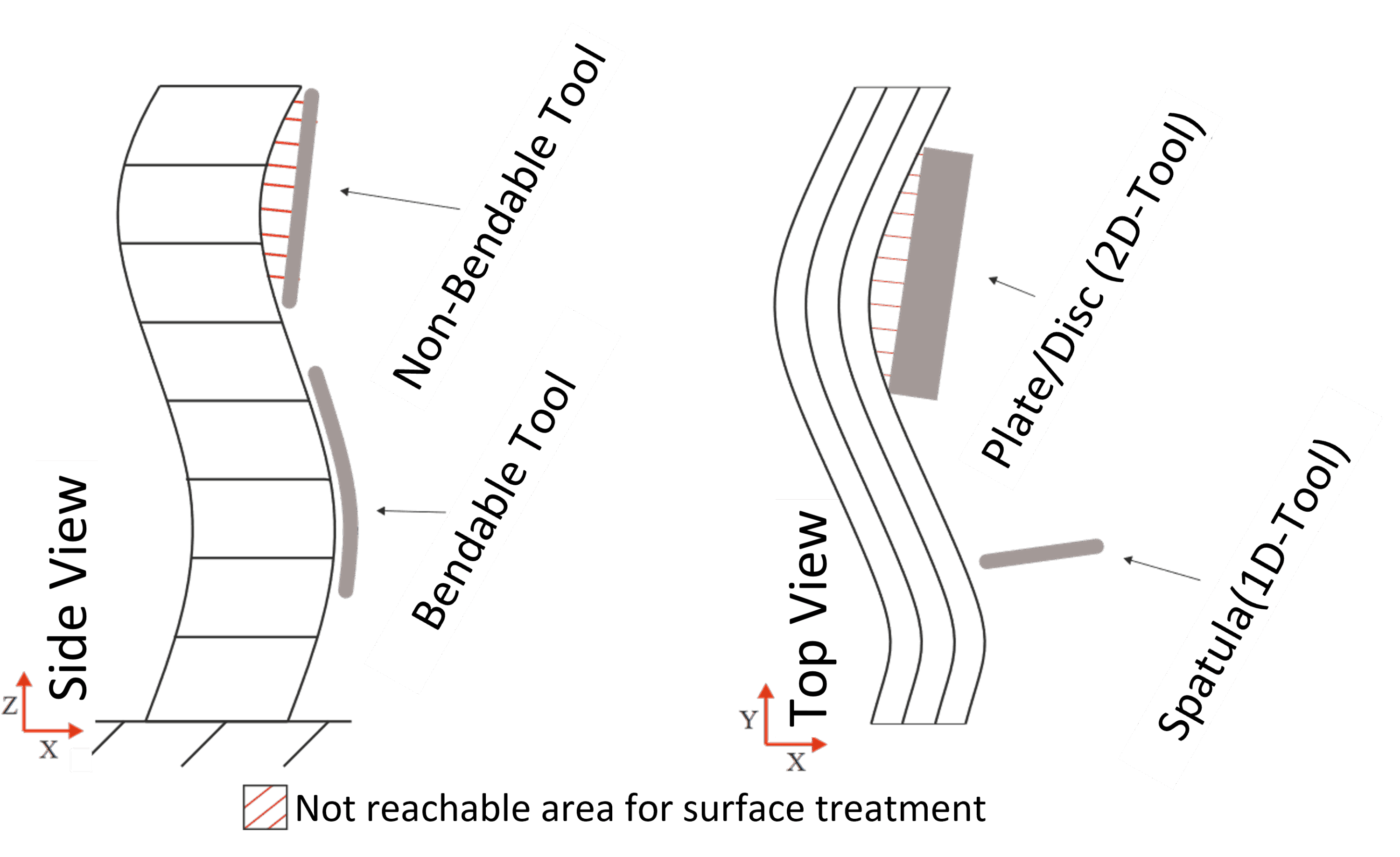

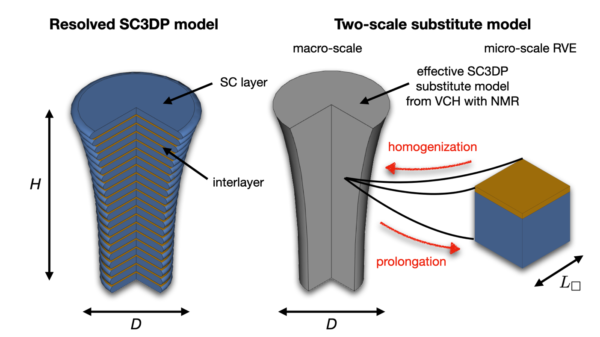

Integrated Additive Manufacturing Processes for Reinforced Shotcrete 3D Printing (SC3DP) Elements with Precise Surface Quality [11.07.2025] Megnet, Manuel; Doctoral Researcher, m.megnet@tu-braunschweig.de Jänicke, Ralf; Project Leader, r.janicke@tu-braunschweig.de Kollmannsberger, Stefan; Project Leader, stefan.kollmannsberger@uni-weimar.de TU Braunschweig, IAM and Bauhaus-Universität Weimar, IBMB Main Goal Project A04 aims to investigate innovative Additive Manufacturing (AM) processes based on Shotcrete 3D Printing (SC3DP) for the production of material-efficient, force-optimised, reinforced, load-bearing concrete components with a …

Research Summary Report of B06

Category: Research Summary Report

Material modelling and simulation of deposition additive manufacturing processes on a part scale [18.09.2025] La, Quoc Tuan; Doctoral Researcher,quoc-tuan.la@tu-braunschweig.de Jänicke, Ralf; Project Leader, r.janicke@tu-braunschweig.de Kollmannsberger, Stefan; Project Leader, stefan.kollmannsberger@uni-weimar.de TU Braunschweig, IAM and Bauhaus-Universität Weimar, IBMB Main Goal The main objective of this project is to predict structural failures in Shotcrete 3D Printing (SC3DP), a process in which a concrete mix is deposited using pressurized air. To achieve …

Research Summary Report of A02

Category: Research Summary Report

Particle-Bed 3D Printing by Selective Cement Paste Intrusion (SPI) – Particle Surface Functionalisation, Particle Synthesis and Integration of WAAM Reinforcement [10.09.2025] Hamilton, Leigh Duncan; Doctoral Researcher, L.Hamilton@tu-braunschweig.de Zetzener, Harald; Leading researcher, H.Zetzener@tu-braunschweig.de Kwade, Arno; Project Leader, A.Kwade@tu-braunschweig.de TU Braunschweig, Institute for Particle Technology Main Goal To enable selective paste intrusion (SPI) for practical …

Research Summary Report of A03

Category: Research Summary Report

Extrusion of Near-Nozzle Mixed Concrete – Individually Graded in Density and in Rate of 3D Fibre Reinforcement [05.09.2025] Cheng, Shengbo; Doctoral Researcher, shengbo.cheng@tum.de Bos, Freek; Project Leader, freek.bos@tum.de TU Munich, Chair of Concrete and Masonry Structures (mb) Main Goal With the near nozzle mixing (NNM) approach in A03, functionally graded 3D concrete printing (3DCP) has been established as a feasible process. Building on the concept of material gradation and the development of ‘Gradation-ready extrusion system (GRES)’, continues transitions from lightweight concrete to normal concrete …

Research Summary Report of A05

Category: Research Summary Report

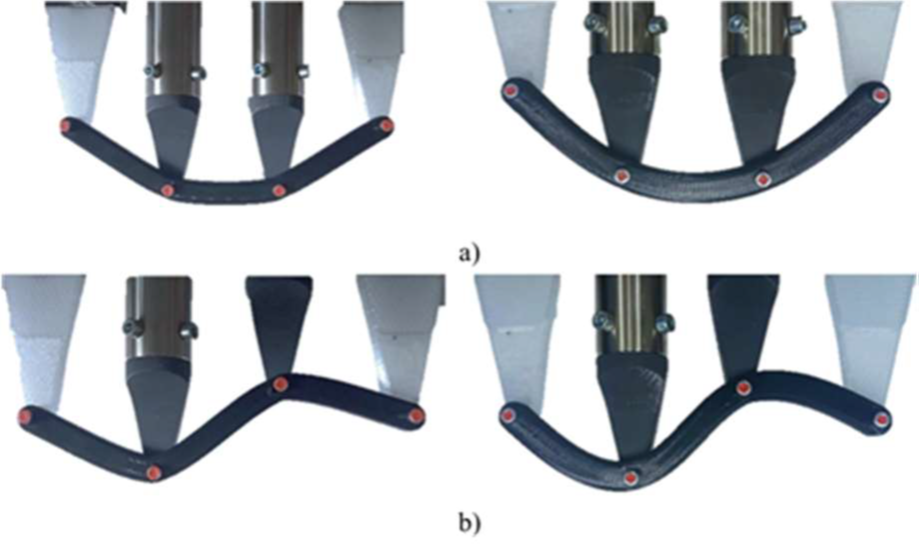

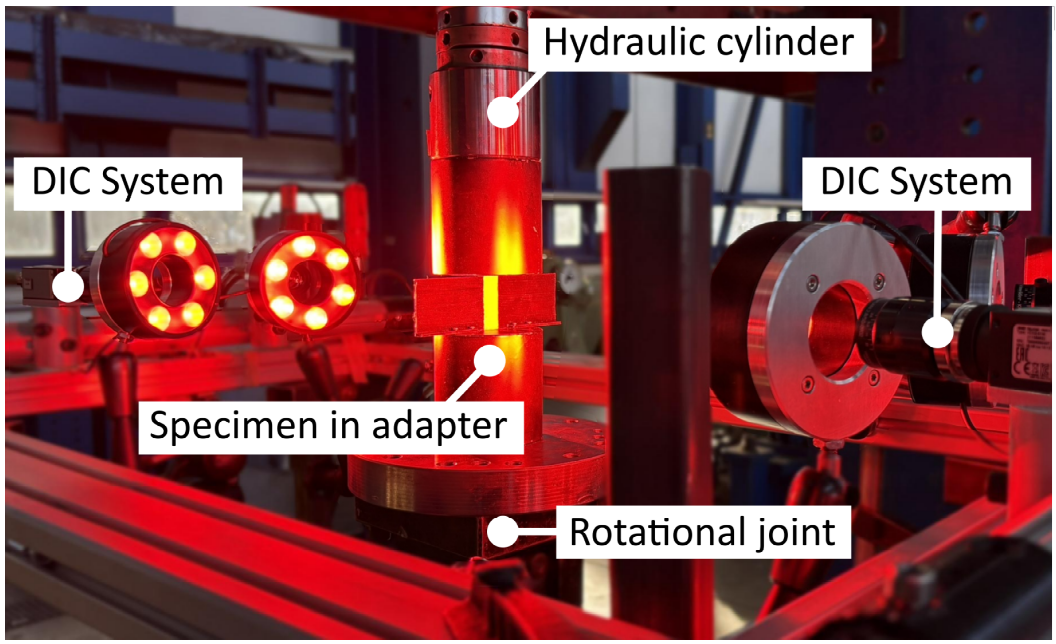

Integration of Individualized Prefabricated Fibre Reinforcement in Additive Manufacturing with Concrete [22.08.2025] Thiele, Philip; Doctoral Researcher, philip.thiele@tu-braunschweig.de Hühne, Christian; Project Leader, christian.huehne@tu-braunschweig.de TU Braunschweig, Institute of Mechanics and Adaptronics (IMA) The individual integration of fibre reinforcement into large additively manufactured concrete components allows new design freedom and reduces concrete consumption due to reduced concrete cover. Strategies for the integration of freely formable reinforcing strands for different AM processes are being developed in project A05. A Dynamic Winding Machine is used to prepare reinforcement strands. …

Research Summary Report of A06

Category: Research Summary Report

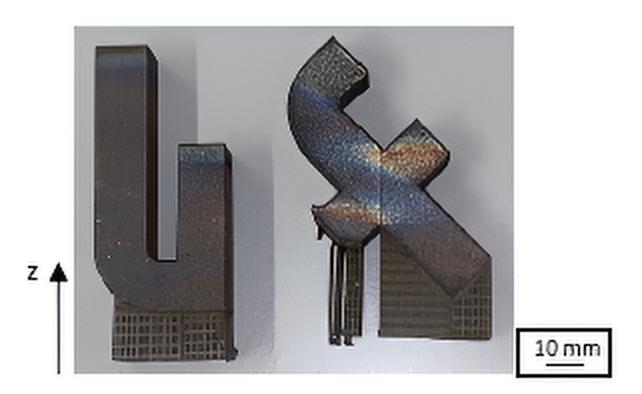

Laser Powder-Bed Fusion (LPBF) of Steel Elements for Construction – Basics of Design and Mechanical Resilience [08.08.2025] Suchowerchov, Julia; Doctoral Researcher, julia.suchowerchov@tum.de Technical University of Munich, Institute for Machine Tools and Industrial Management Blankenhagen, Jakob; Doctoral Researcher, jakob.blankenhagen@tum.de Technical University of Munich, Chair of Metal Structures Summary The project A06 aims to develop a methodology for producing safe and functional structural steel elements for the construction industry using laser powder bed fusion (LPBF). The LPBF steel Printdur HSA® will be qualified by using and transferring methodologies …

Research Summary Report of A04

Category: Research Summary Report

Integrated Additive Manufacturing Processes for Reinforced Shotcrete 3D Printing (SC3DP) Elements with Precise Surface Quality [11.07.2025] Megnet, Manuel1; Doctoral Researcher, m.megnet@tu-braunschweig.de Dröder, Klaus1; Project leader, k.droeder@tu-braunschweig.de TU Braunschweig, Institute of Machine Tools and Production Technology (IWF) Main Goal: Project A04 aims to investigate innovative Additive Manufacturing (AM) processes based on Shotcrete 3D Printing (SC3DP) for the production of material-efficient, force-optimised, reinforced, loadbearing concrete components with a precise surface quality and geometrical precision. The goal is to enable the production of large-scale concrete elements with …

Research Summary Report of A07

Category: Research Summary Report

Wire and Arc Additive Manufacturing (WAAM) of Complex Individualized Steel Components [04.07.2025] M. Sc. Marc Müggenburg Researcher, marc.mueggenburg@tu-braunschweig.de Dr.-Ing. Julian Unglaub Project leader, j.unglaub@tu-braunschweig.de Technical University of Braunschweig, Institute of Steel Structures A07 focuses on developing load-specific, individual high-strength low-alloy steel DED-Arc components, understanding strengthening solutions for existing structures and designing various manufacturing strategies. The specific challenges of adaptive design and adaptive manufacturing of different scale components will be addressed and a digital twin including data from the design and manufacturing process, surface geometry and component performance will …

Research Summary Report of C06

Category: Research Summary Report

Integration of Additive Manufacturing in the Construction Process [13.06.2025] M. Sc. Karam Mawas Researcher, k.mawas@tu-braunschweig.de M. Sc. Mohammad Savadkouhi Researcher, mohammad.savadkouhi-aghamolki@tu-braunschweig.de Dr.-Ing. Mehdi Maboudi Researcher, m.maboudi@tu-braunschweig.de Prof. Dr.-Ing. Markus Gerke Project leader, m.gerke@tu-braunschweig.de Technical University of Braunschweig, Institute of Geodesy and Photogrammetry (IGP) Quality control plays a pivotal role in enabling the seamless integration of components into objects, and …

Research Summary Report of A10

Category: Research Summary Report

Earth Additive Manufacturing (EAM) – Material and Process Combinations for AM with Earth-based Materials [25.06.2025] B. Sc. Sofia Tsiotou Researcher, sofia.tsiotou@tum.de Prof. Dr. (PhD) Alisa Machner Project leader, alisa.machner@tum.de Technical University of Munich, TUM School of Engineering and Design, Professorship for Mineral Construction Materials Project A10 aims to design and investigate two novel processes for Earth Additive Manufacturing (EAM), namely, Sprayed Earth Additive Manufacturing (SEAM) as a deposition-based EAM process, and Intrusion Earth Additive Manufacturing (IEAM) as a particle-bed-based EAM process. Alongside the investigations on the two processes, earthen binder mixtures will be evaluated from a material’s perspective …