News

Research Summary Report of A04

Category: Research Summary Report

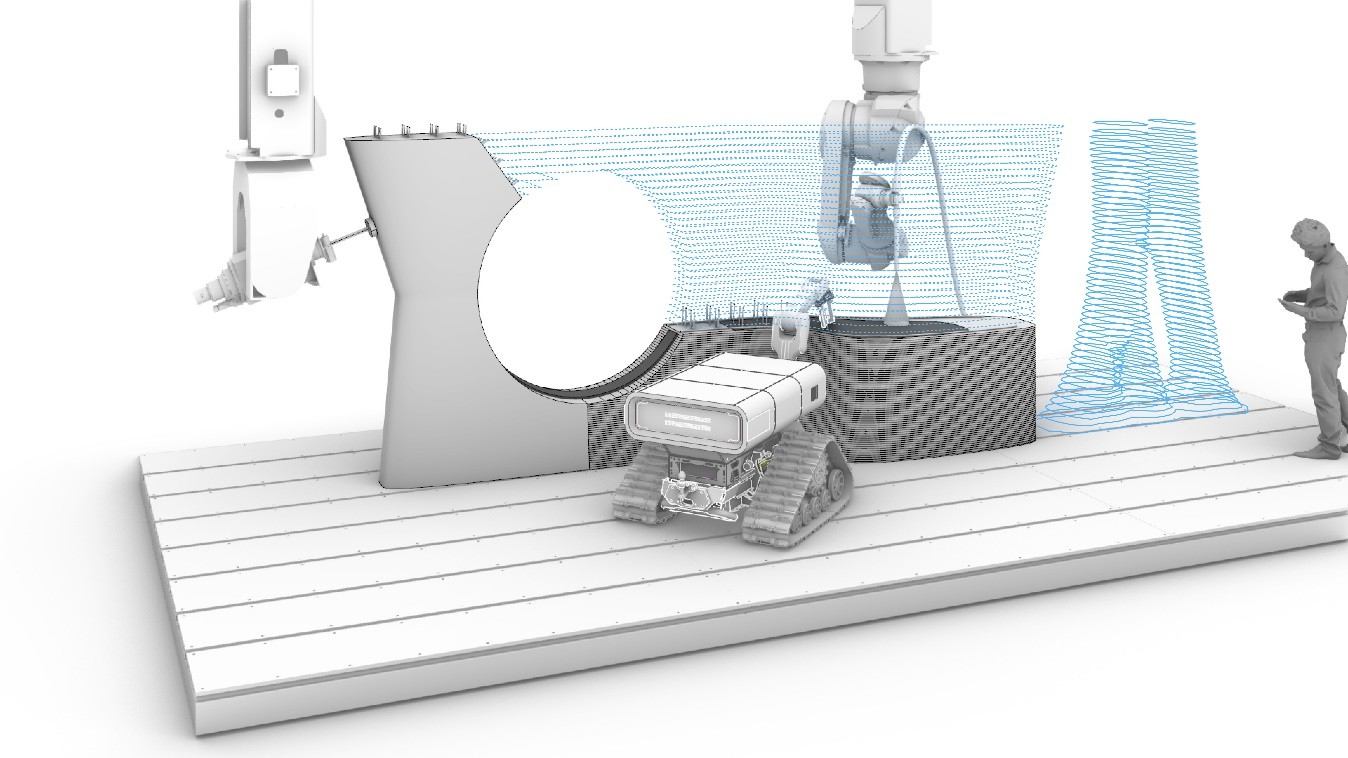

Integrated Additive Manufacturing Processes for Reinforced Shotcrete 3D Printing (SC3DP) Elements with Precise Surface Quality [29.01.2025] M. Sc. Robin Dörrie Researcher, r.doerrie@tu-braunschweig.de Technische Universität Braunschweig(TU BS), ITE Institute of Structural Design The project aims to fundamentally understand the Shotcrete 3D Printing (SC3DP) technology to manufacture sustainable, multi-objective optimised, reinforced concrete components with precise surface quality and improved building physics via functional integration. It seeks to minimise the carbon footprint of 3D printed structures by exploring various material strategies, such as reducing cement content by increasing the aggregate size or replacing cement with a different binder and design methods to optimise the usage of concrete in order to decrease the …

Research Summary Report of A03

Category: Research Summary Report

Extrusion of Near-Nozzle Mixed Concrete – Individually Graded in Density and in Rate of 3D Fibre Reinforcement [22.01.2025] M. Eng. Benedikt Grimm Researcher, benedikt.grimm@tum.de M. Sc. Christian Maximilian Hechtl Researcher, m.hechtl@tum.de Dr.-Ing. Thomas Kränkel Project leader, thomas.kraenkel@tum.de Prof. Dr.-Ing. Christoph Gehlen Project leader, gehlen@tum.de Technische Universität München(TUM), Chair of Material Science and Testing The goal of A03 is to establish a concrete extrusion process using a near nozzle mixing (NNM) approach to enable the gradual variation of material properties during printing (gradation). This approach allows for the creation of multifunctional components, such as structures …

Research Summary Report of C09

Category: Research Summary Report

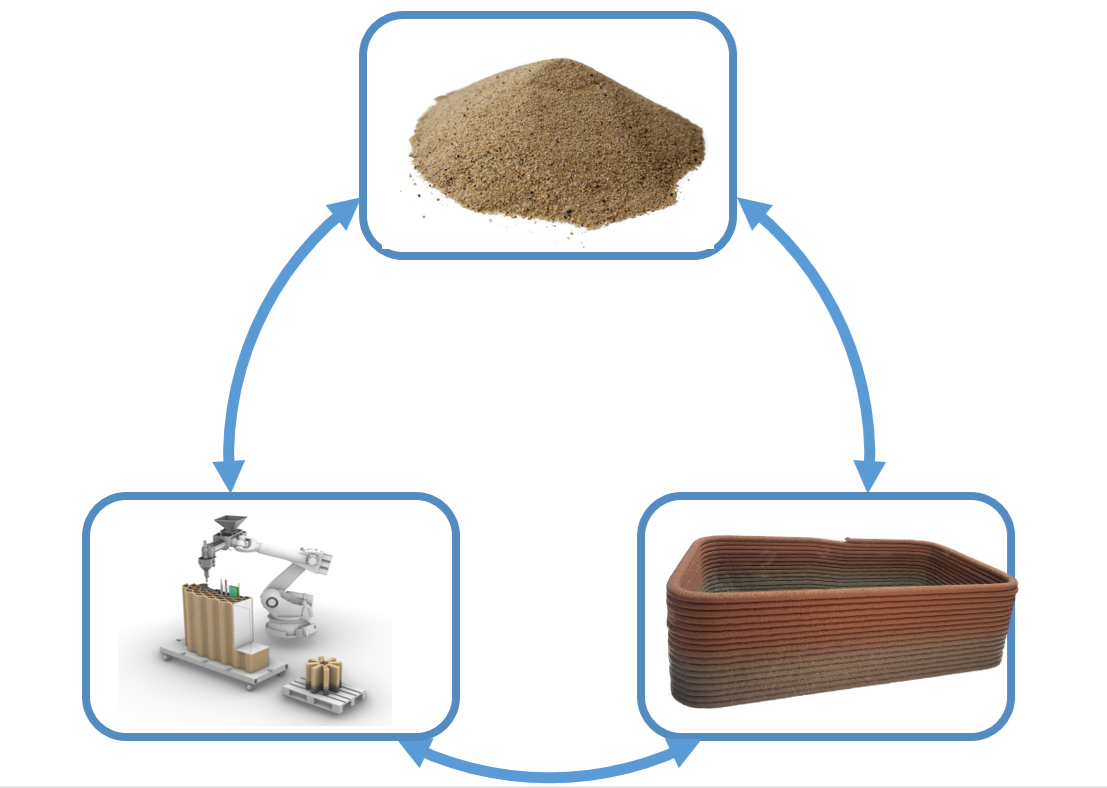

Environmental Life Cycle Assessment – Determination of Ecological Sustainability Potentials by AMC [11.12.2024] M. Eng. Sophie Viktoria Albrecht Researcher, Sophie.albrecht@oth-regensburg.de Prof. Charlotte Thiel Project leader, charlotte.thiel@oth-regensburg.de Ostbayerische Technische Hochschule Regensburg (OTH), Construction Materials C09 aims to enhance the ecological sustainability of Additive Manufacturing in Construction (AMC) by quantifying and optimizing its environmental benefits through comprehensive Life Cycle Assessments (E-LCA) from cradle to cradle. This involves developing transparent Product Environmental Footprint Category Rules (PEFCR), identifying impactful reduction measures, and integrating circular design strategies to create durable, efficient, and reusable components. By incorporating these findings into Fabrication Information Modelling (FIM), C09 enables early-stage, sustainability-focused decision-making, fostering material-efficient, low-impact construction practices and reducing the environmental footprint of the building …

Research Summary Report of B06

Category: Research Summary Report

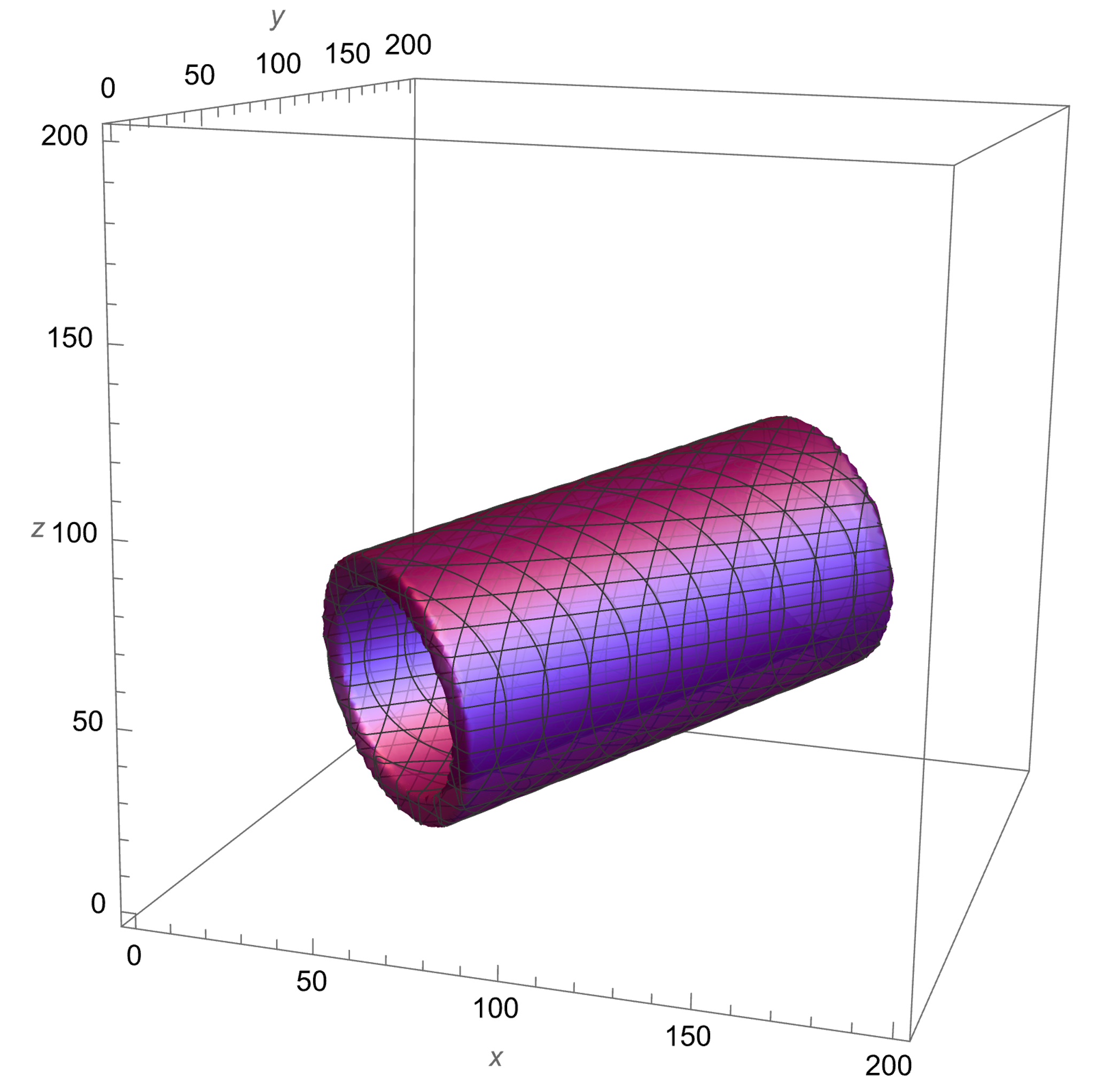

Material Modelling and Simulation of Deposition AM Processes on the Part Scale [11.12.2024] M. Sc. Quoc Tuan La Researcher, quoc-tuan.la@tu-braunschweig.de Prof. Dr.-Ing. Ralf Jänicke Project leader, r.janicke@tu-braunschweig.de Technische Universität Braunschweig, Institute of Applied Mechanics Prof. Dr.-Ing. habil. Stefan Kollmannsberger Project leader, stefan.kollmannsberger@uni-weimar.de Bauhaus-Universität Weimar, Professorship of Data Engineering in Civil Engineering The main goal of the project is to simulate the deposition process of additive manufacturing for complex geometries. The simulation focuses on Shotcrete 3D Printing (SC3DP) and includes identifying and calibrating a thixotropic material model. Additionally, Variationally consistent Computational Homogenization is employed to minimize computational costs. Summary Shotcrete 3D Printing (SC3DP) is a soft material that hardens over time through structure formation …

Research Summary Report of A01

Category: Research Summary Report

Particle-Bed 3D Printing by Selective Cement Activation (SCA) – Sustainability, process enhancement and material models [04.12.2024] M. Sc. Friedrich Herding Researcher, friedrich.herding@tum.de Prof. Dr.-Ing. Dirk Lowke Project leader, lowke@tum.de TU Munich (TUM), Chair of Binder Jetting Technology Our main research objective is the fundamental understanding of the material-process interactions in particle bed 3D printing (PB3DP) by Selective Cement Activation (SCA). This will allow for the manufacturing of concrete elements with high mechanical strength and dimensional accuracy. Besides we also investigate different ways of reinforcement integration, which is crucial for the manufacturing of load-bearing building components. Summary Selective Cement Activation (SCA) is a particle bed 3D printing technique that offers the possibility to precisely manufacture free-form …

Research Summary Report of A10

Category: Research Summary Report

Earth Additive Manufacturing (EAM) – Material and Process Combinations for AM with Earth-based Materials [29.11.2024] M. A. Ema Krakovská Researcher, ema.krakovska@tum.de Prof. Dr. Kathrin Dörfler Project leader, doerfler@tum.de all: TU Munich (TUM), Professorship of Digital Fabrication The main research objective of A10 is the conception and investigation of two novel Earth Additive Manufacturing (EAM) processes, their material-process interactions, and their evaluation in large-scale architectural applications. Focusing on the characterisation of earth-based material mixtures (PL Machner), the project investigates a) Sprayed Earth Additive Manufacturing (SEAM) as a deposition-based process (PL Kloft) and b) Intrusion Earth Additive Manufacturing (IEAM) as a particle-bed-based process (PL Dörfler). The research aims to assess earth-based materials for these processes with a …

Research Summary Report of C02

Category: Research Summary Report

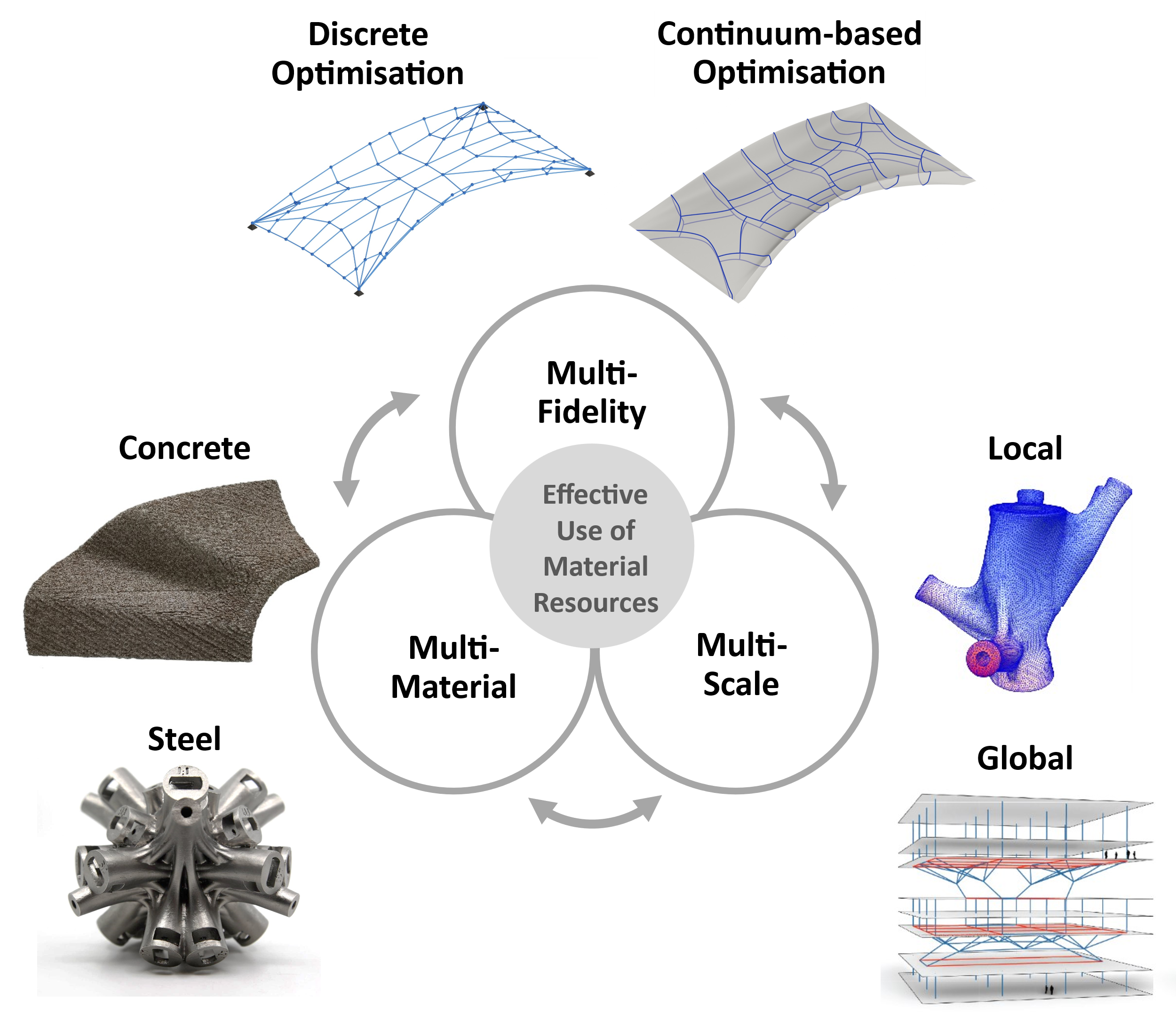

3D Structural Puzzle – Numerical Multi Scale Shape and Topology Optimisation Methods to Additively Manufacture Optimal Structures from Optimised Pieces [27.11.2024] M. Sc. Philipp Jakobs Researcher, philipp.jakobs@tum.de Prof. Dr.-Ing. Roland Wüchner Project leader, wuechner@tum.de all: TU Munich (TUM), Chair of Structural Analysis Current building practices often adopt a sequential design approach, where architectural, structural, and fabrication aspects are addressed independently, resulting in excessive material consumption. The CO2 project aims to establish a Holistic Design Framework (HDF) integrating the above-mentioned aspects. Within this framework, additive manufacturing facilitates structural optimisation by enabling the production of bespoke geometries for an effective use of material resources. Departing from the conventional sequential approach, the HDF concurrently integrates low-fidelity Discrete Optimisation Approaches …

Research Summary Report of A02

Category: Research Summary Report

Particle-Bed 3D Printing by Selective Cement Paste Intrusion (SPI) – Particle Surface Functionalisation, Particle Synthesis and Integration of WAAM Reinforcement [20.11.2024] M. Sc. Alexander Straßer Researcher, alexander.strasser@tum.de Dr.-Ing. Thomas Kränkel Researcher, thomas.kraenkel@tum.de Prof. Dr.-Ing. Christoph Gehlen Project leader, gehlen@tum.de all: TU Munich (TUM), Chair of Materials Science and Testing The goal of A02 is to implement reinforcement by Wire and Arc Additive Manufacturing (WAAM) in concrete elements produced by Selective Paste Intrusion (SPI), see Figure 1. The SPI and combined SPI + WAAM process will also be further investigated with a focus on ecological improvements. Both individual processes will first be examined separately. To achieve these goals, the SPI process will include optimization …

Discover the Future of Construction: AMC at formnext, Frankfurt

Category: Press release

Frankfurt, November 2024 – From November 20–22, 2024, the Collaborative Research Center TRR 277 “Additive Manufacturing in Construction” (AMC) will present its cutting-edge research and innovations at formnext / Built Environment Additive Manufacturing BE-AM Exhibition 2024 📍 Location: Hall 11, Booth 47-49 The AMC team will feature interactive exhibits that highlight advancements in additive manufacturing technologies for construction. Visitors are encouraged to join us for engaging discussions on how digital and additive manufacturing is transforming construction processes and materials. Keynote Highlight: Norman Hack (TU Braunschweig) Don’t miss the keynote by Norman Hack, a leading expert in digital and additive construction and Professor at TU Braunschweig. His talk, titled “Advances in Additive Manufacturing for Construction,” will explore groundbreaking projects developed within …

Research Summary Report of C05

Category: Research Summary Report

Jointing Principles for Combination of Concrete Elements Produced by Different Additive Manufacturing Processes [14.11.2024] Prof. Dr.-Ing. Harald Kloft Project leader, h.kloft@tu-braunschweig.de Dr.-Ing. Abtin Baghdadi Researcher, a.baghdadi@tu-braunschweig.de Dipl.-Ing. Lukas Ledderose Researcher, l.ledderose@tu-braunschweig.de TU Braunschweig, Institute of Structural Design (ITE) Prof. Dr.-Ing. Martin Empelmann Project leader, m.empelmann@ibmb.tu-braunschweig.de TU Braunschweig, Institute of Building Materials, Concrete Construction and Fire Safety (iBMB) In the second phase of the C05 project, research will focus on advancing connection methods and robotic manufacturing techniques, such as waterjet cutting and stamping in green-state concrete, while incorporating post-tensioning and steel connectors for higher load-bearing capacity and easier assemblage of AM concrete segments. The project will explore new design …

Research Summary Report of B03

Category: Research Summary Report

Modelling and Simulation of Shotcrete 3D Printing (SC3DP) Based on a Massively Parallel Multi-Phase, Multi-Component Coupled LBM-DEM Approach [14.11.2024] Prof. Dr. rer. nat. M. Geier Project leader, geier@irmb.tu-bs.de Dr.-Ing. K. Kutscher Researcher, kutscher@irmb.tu-bs.de Prof. Dr.-Ing. habil. M. Krafczyk Project leader, kraft@irmb.tu-bs.de Dr.-Ing. H. Alihussein Researcher, hussein@irmb.tu-bs.de TU Braunschweig, Institute for Computational Modeling in Civil Engineering, IRMB (Institut für rechnergestützte Modellierung im Bauingenieurwesen) The project is currently concerned with the simulation of a moving nozzle for the injection process using I3DCP. We are particularly interested in the influence of the movement of the nozzle on the printed strand. Summary The I3DCP is a three-phase problem where the …

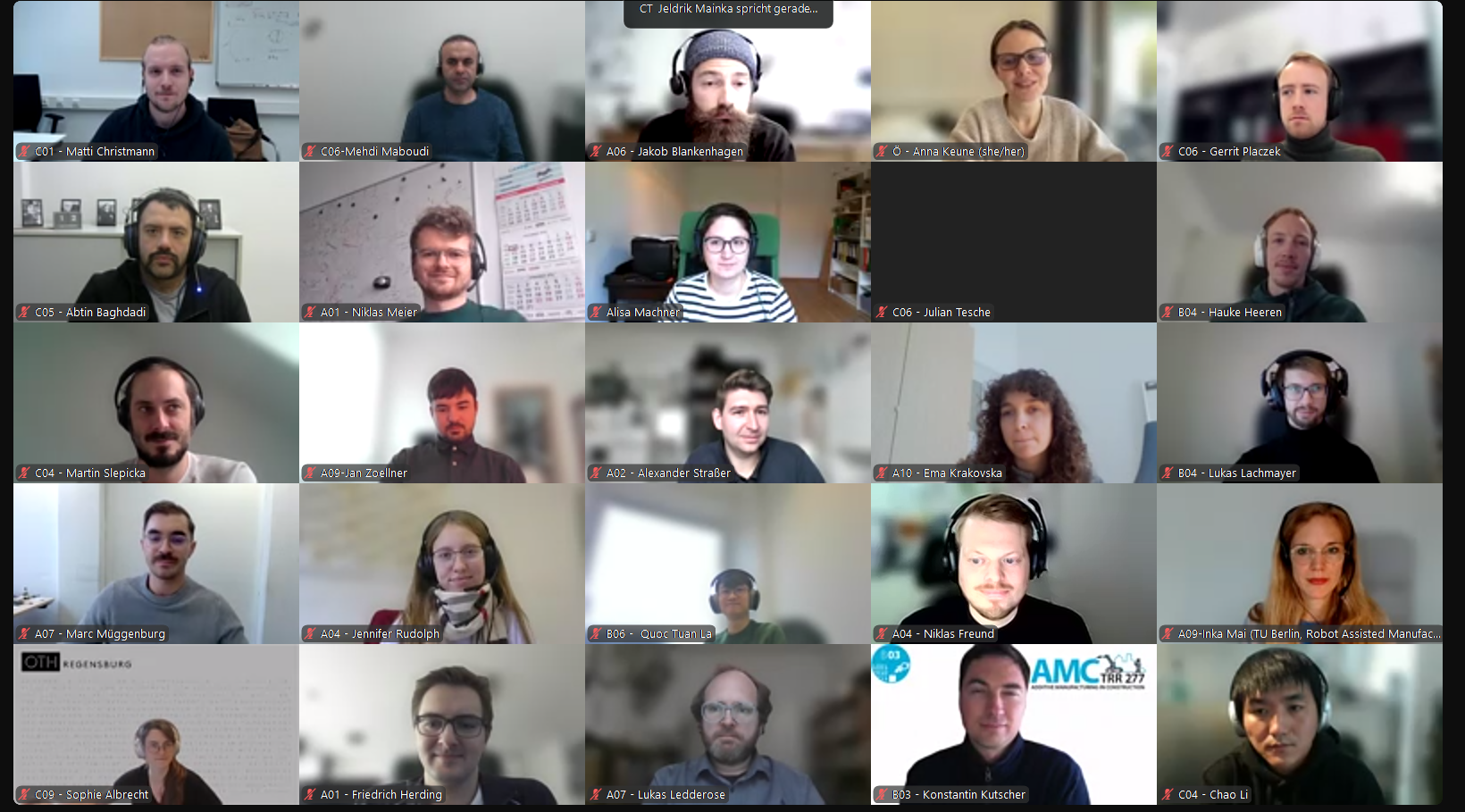

Press release: Strong Network for Research Progress

Category: Press release

Braunschweig/Munich, November 2024 – AMC Meeting Focuses on Publication Strategies and Discusses Sustainable 3D Printing Applications in Construction On November 11 and 12, 2024, over 70 scientists from the Collaborative Research Center AMC TRR 277 gathered online for the quarterly Cross-Project Workshop to present recent project developments, publication strategies, and networking plans for the second funding period. The meeting offered an important platform for aligning projects and laying the groundwork for continued collaboration. The core focus of AMC TRR 277 is advancing 3D printing as a key technology for a future-oriented construction industry. The research aims to unlock the vast potential of this technology for construction and to develop practical applications that are feasible in the long term. This …

Research Summary Report of A03

Category: Research Summary Report

Extrusion of Near-Nozzle Mixed Concrete –Individually Graded in Density and in Rate of 3D Fibre Reinforcement [30.10.2024] Dr. Ing. Bos, Freek Project leader, freek.bos@tum.de Cheng, Shengbo Researcher, shengbo.cheng@tum.de Technical University of Munich, Chair of Concrete and Masonry Structures (Lehrstuhl für Massivbau) Extrusion-based 3D Concrete Printing (3DCP) is the most widely investigated technology for additive manufacturing (AM) in construction. Near-Nozzle Mixing (NNM) has been introduced in the 1st funding period of project A03 as a variant that can overcome several limitations of conventional 3DCP. Instead of mixing at a distance, NNM mixes the material constituents at the print head, thereby drastically reducing the transportation distance through hoses and the associated pumping pressure required. Thus, pumping-related …

Press release: Hands-on research with the 3D printer at the Long Night of Museums in Munich

Category: Press release

Munich, October 2024 – The Collaborative Research Center Additive Manufacturing in Construction /TRR 277 AMC made a significant impact at the Long Night of Museums in Munich, held at the iconic Deutsches Museum. As part of the 25th anniversary of the city-wide cultural event, AMC brought cutting-edge construction technology to life through hands-on workshops and live demonstrations, sparking immense public interest. Making research tangible At the TUMlab, AMC researchers led by Anna Keune and the Ö project organised the ‘Clay Houses’ workshop, where participants explored the world of 3D design. Visitors created digital 3D models using TinkerCad, which were then transformed into physical clay objects. This interactive experience allowed nearly 200 attendees to engage with 3D printing in construction, blending …

Research Summary Report of C04

Category: Research Summary Report

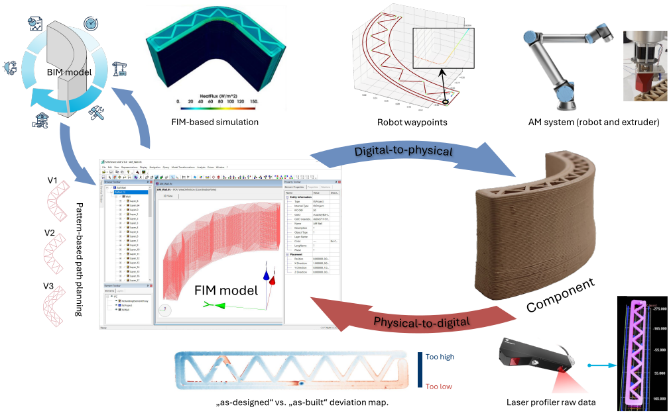

Integrating Digital Design and Additive Manufacturing through BIM-Based Decision Support and Digital Twin Methods [04.10.2024] Borrmann, André Project leader, andre.borrmann@tum.de Slepicka, Martin Researcher,martin.slepicka@tum.de All: Technical University of Munich, Chair of Computational Modeling and Simulation Additive Manufacturing (AM) is gaining more and more interest in the construction sector as it potentially offers many advantages, such as increased geometric freedom and productivity. However, these advantages come at a cost; additional effort is required in the data preparation for AM (a higher level of detail is necessary). Project C04 aims to simplify and streamline the necessary design and control processes and to interlink digital design (i.e. BIM) with automated fabrication. For this purpose, the Fabrication Information …

Research Summary Report of A02

Category: Research Summary Report

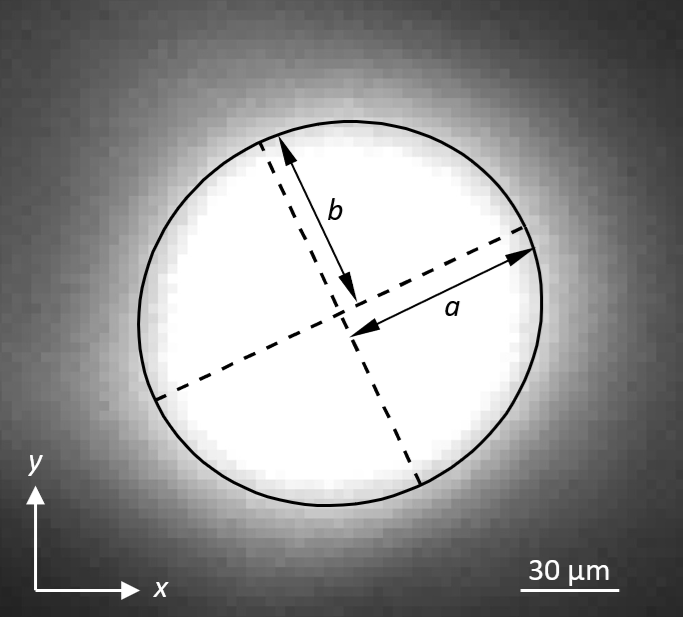

Particle-Bed 3D Printing by Selective Cement Paste Intrusion (SPI) – Particle Surface Functionalisation, Particle Synthesis and Integration of WAAM Reinforcement [27.09.2024] Hamilton, Leigh Duncan; Doctoral researcher; L.Hamilton@tu-braunschweig.de Zetzener, Harald; Leading researcher; H.Zetzener@tu-braunschweig.de Kwade, Arno; Project leader; A.Kwade@tu-braunschweig.de All: TU Braunschweig, Institute for Particle Technology To enable selective paste intrusion (SPI) for practical applications, the inclusion of reinforcement is mandatory. The focus of the first funding period was uniting SPI with wire arc additive manufacturing (WAAM) for reinforced concrete as well as functionalising and/or modifying particulate systems. During the first funding period, two main issues were identified: the need for ecological sustainable development for the combined process of SPI+WAAM and accelerated process velocities to improve the economic efficiency. Therefore, the …

Research Summary Report of A05

Category: Research Summary Report

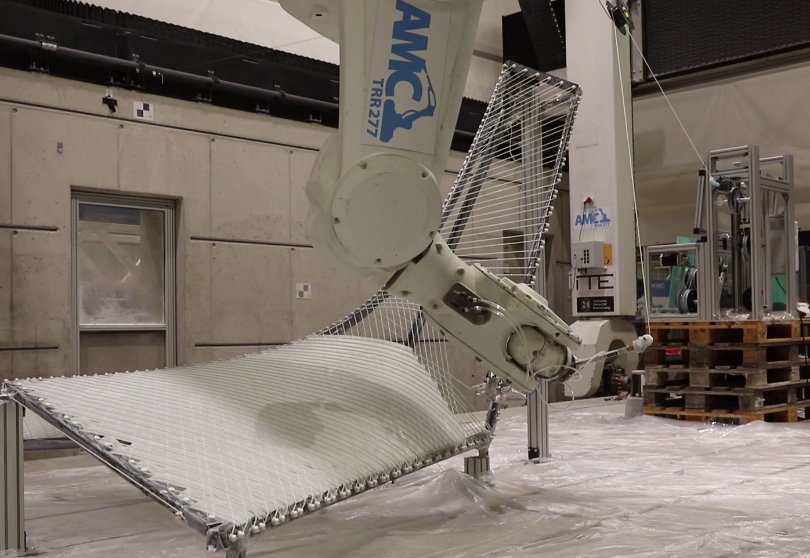

Integration of Individualized Prefabricated Fibre Reinforcement in Additive Manufacturing with Concrete [24.09.2024] Rothe, Tom; Doctoral researcher, t.rothe@tu-braunschweig.de, TU Braunschweig, Institute of Mechanics and Adaptronics (IMA) Hühne, Christian; Project Leader, Christian.Huehne@tu-braunschweig.de, TU Braunschweig, Institute of Mechanics and Adaptronics (IMA) The individual integration of fibre reinforcement into large additively manufactured concrete components allows new design freedom and reduces concrete consumption due to reduced concrete cover. Strategies for the integration of freely formable reinforcing strands for different AM processes are being developed in project A05. A Dynamic Winding Machine is used to prepare reinforcement strands. This machine is used to consolidate and impregnate a primary fibre strand and wind a secondary yarn around it as a surface structuring. Thus, these reinforcement strands …

Focus on Innovative Construction Technologies: Practical Workshops on Digital Fabrication

Category: Press release

20 International PhD Students Visit Braunschweig At the beginning of September, TU Braunschweig became a hub for 20 young researchers attending a workshop in conjunction with the Digital Concrete 2024 conference. From September 1 to 3, these PhD students had the chance to experience cutting-edge research approaches and advanced infrastructure related to digital construction and fabrication processes firsthand. The workshops provided a hands-on introduction to Shotcrete 3D Printing and cyber-physical manufacturing technologies. Participants could dive deeper into the world of digital construction through technical presentations and practical sessions at the Digital Building Fabrication Laboratory (DBFL) and the Digital Construction Site (DCS). They followed each step of the construction process, from design to cyber-physical production, with the option to choose …

Research Summary Report of A06

Category: Research Summary Report

Integrated Additive Manufacturing Processes for Reinforced Shotcrete 3D Printing (SC3DP) Elements with Precise Surface Quality [09.09.2024] Wenzler, David; doctoral researcher; david.wenzler@tum.de Technical University of Munich, Institute for Machine Tools and Industrial Management Blankenhagen, Jakob; doctoral researcher; jakob.blankenhagen@tum.de Technical University of Munich, Chair of Metal Structures Summary The project A06 aims to develop a methodology for producing safe and functional structural steel elements for construction using laser powder-bed fusion (LPBF). The LPBF steel Printdur HSA® will be qualified by using and transferring methodologies from the first funding period. The prediction of fatigue behaviour based on process monitoring data and machine learning will be explored. Lattice structures will be used to tailor the stiffness of the steel elements. These complex LPBF …

Digital Concrete 2024

400 scientists and one question: How will 3D-printing get to the construction site? At the Digital Concrete Conference 2024, international scientists met to discuss research findings, challenges and new technologies relating to 3D-printing in the construction industry and their requirements for materials and processes. Munich, September, 2024 – Digital Concrete 2024 concluded with great success, bringing together over 400 enthusiastic participants from around the globe for three exhilarating days of innovation, collaboration, and fun. From September 4-6, the 4th RILEM International Conference on Concrete and Digital Fabrication transformed Munichs Science Congress Center into a vibrant hub of creativity and cutting-edge technology. The event featured over 200 presentations across four dynamic parallel sessions, covering an impressive range of topics – from …