Research Summary Report of A07

Wire Arc Additive Manufacturing (WAAM) of High Strength and Individualized Steel Components

[30.01.2026]

Martin Gabriel Altobelli Research Assistant, martin-gabriel.altobelli@mb.tu-chemnitz.de

Kevin Hoefer Research Assistant, kevin.hoefer@mb.tu-chemnitz.de

Jonas Hensel Project Leader, jonas.hensel@mb.tu-chemnitz.de

Technical University of Chemnitz, Institute Institute of Joining and Assembly

The objective of A07 is to enable the use of WAAM for large-scale structures and in-situ applications by integrating material behavior and manufacturing limitations into a comprehensive Holistic Design Framework (HDF). The steps in the framework involve the implementation of a “learning-by-printing” approach that improves the manufacturing process through online decision-making to reduce process instabilities and geometric deviations. Additionally, the mechanical properties of the resulting components will be investigated through destructive and non-destructive testing, as well as numerical simulations. Furthermore, the integration of design, process, geometric, and testing data enables the creation of a Digital Twin of the manufacturing process. Finally, data from the complete process will be evaluated through a Life Cycle Analysis, in conjunction with C09, to guide improvements from a sustainability perspective.

Summary

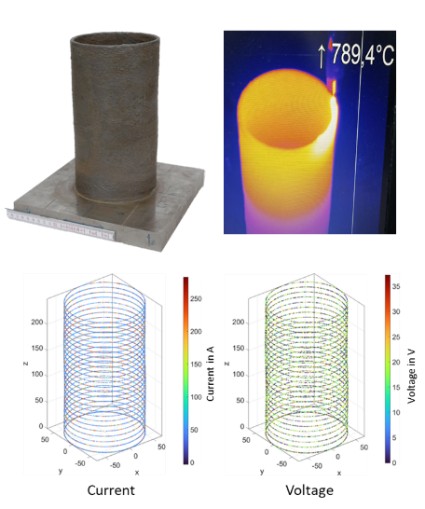

As a first step in creating a digital twin of the process, it is essential to acquire data not only from the process itself but also from the behavior of the resulting components. For this reason, a multi-sensor system was implemented in the manufacturing process. The sensors are capable of recording electrical and thermal data during the material deposition process (see Fig. 1). During the interlayer idle time, the geometric characteristics of each layer are measured using a Laser Profile Sensor (LPS). In this way, the digital shadow is completed. The acquired information enables control of layer height and width through a “learning-by-printing” approach.

Current state of research

The integration of the Laser Profile Sensor (LPS) enables the acquisition of geometric data from the component. The component height is obtained directly from the LPS measurements, facilitating the development of a final height control strategy that reduces geometric deviations between the as-built and as-designed components. This method focuses on correcting the path of the torch and has been validated from simple structures (straight components) and more complex geometries, such as those with overhang regions (see Fig. 2).

In contrast, control of the layer width is achieved by adjusting process parameters such as Wire Feed Rate (WFR) and Travel Speed (TS). The development of this approach is currently at an initial implementation stage. Ongoing research investigates the influence of these parameters on both process behavior and component characteristics. Finally, the application of the “learning-by-printing” approach to a large-scale demonstrator (K-node connector) is under development.