Research Summary Report of A06

Laser Powder-Bed Fusion (LPBF) of Steel Elements for Construction – Basics of Design and Mechanical Resilience

[16.01.2026]

Blankenhagen, Jakob; doctoral researcher; Jakob.blankenhagen@tum.de

Radlbeck, Christina; project leader; c.radlbeck@tum.de

Technical University of Munich, Chair of Metal Structures

Suchowerchov, Julia; doctoral researcher; julia.suchowerchov@tum.de

Technical University of Munich, Institute for Machine Tools and Industrial Management

The project A06 aims to develop a methodology for producing safe and functional structural steel elements for the construction industry using laser powder bed fusion (LPBF). The LPBF steel Printdur HSA® will be qualified by using and transferring methodologies from the first funding period. The prediction of fatigue behaviour based on process monitoring data and machine learning will be explored. Lattice structures will be used to tailor the stiffness of the steel elements. These complex LPBF parts will be integrated into large-scale structures, and their joining with conventional construction steel will be investigated. Data for a reliable life cycle assessment of these LPBF parts will be collected during the project.

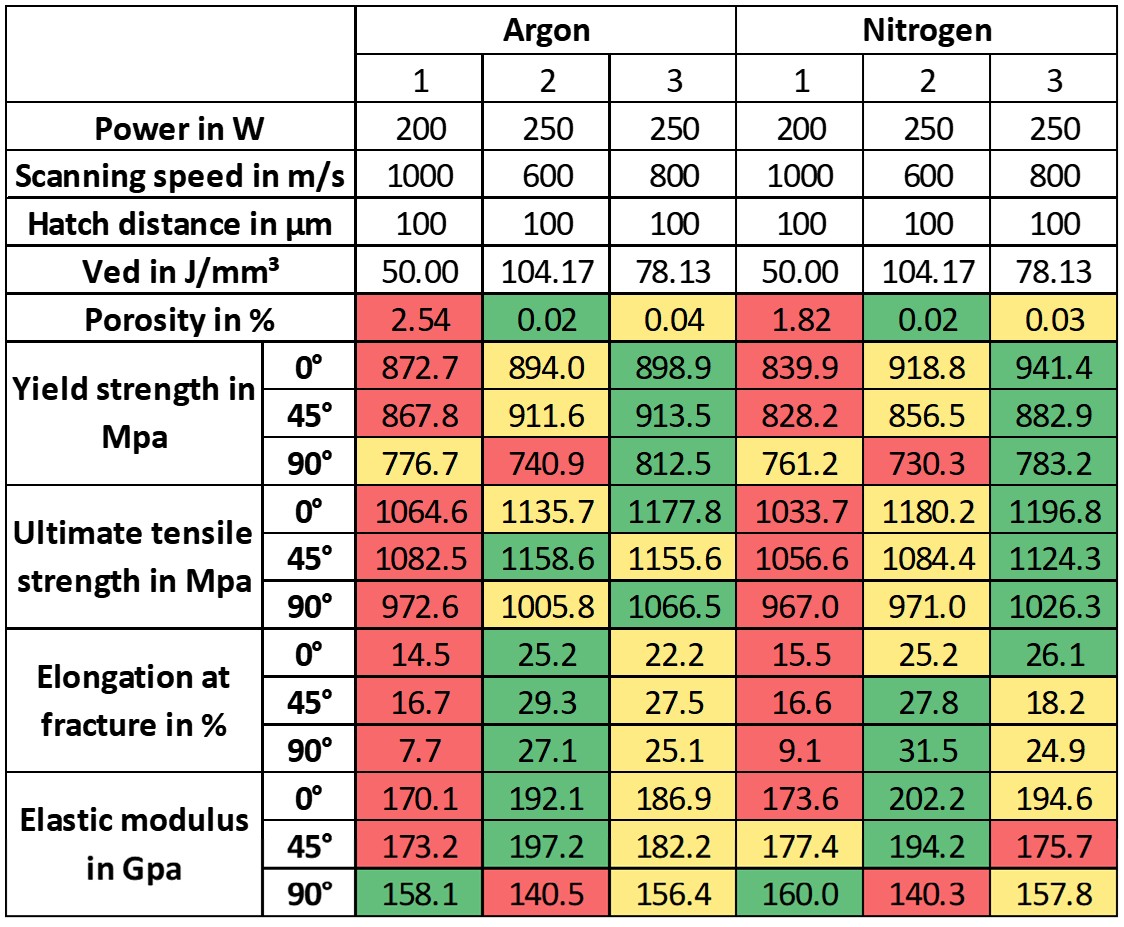

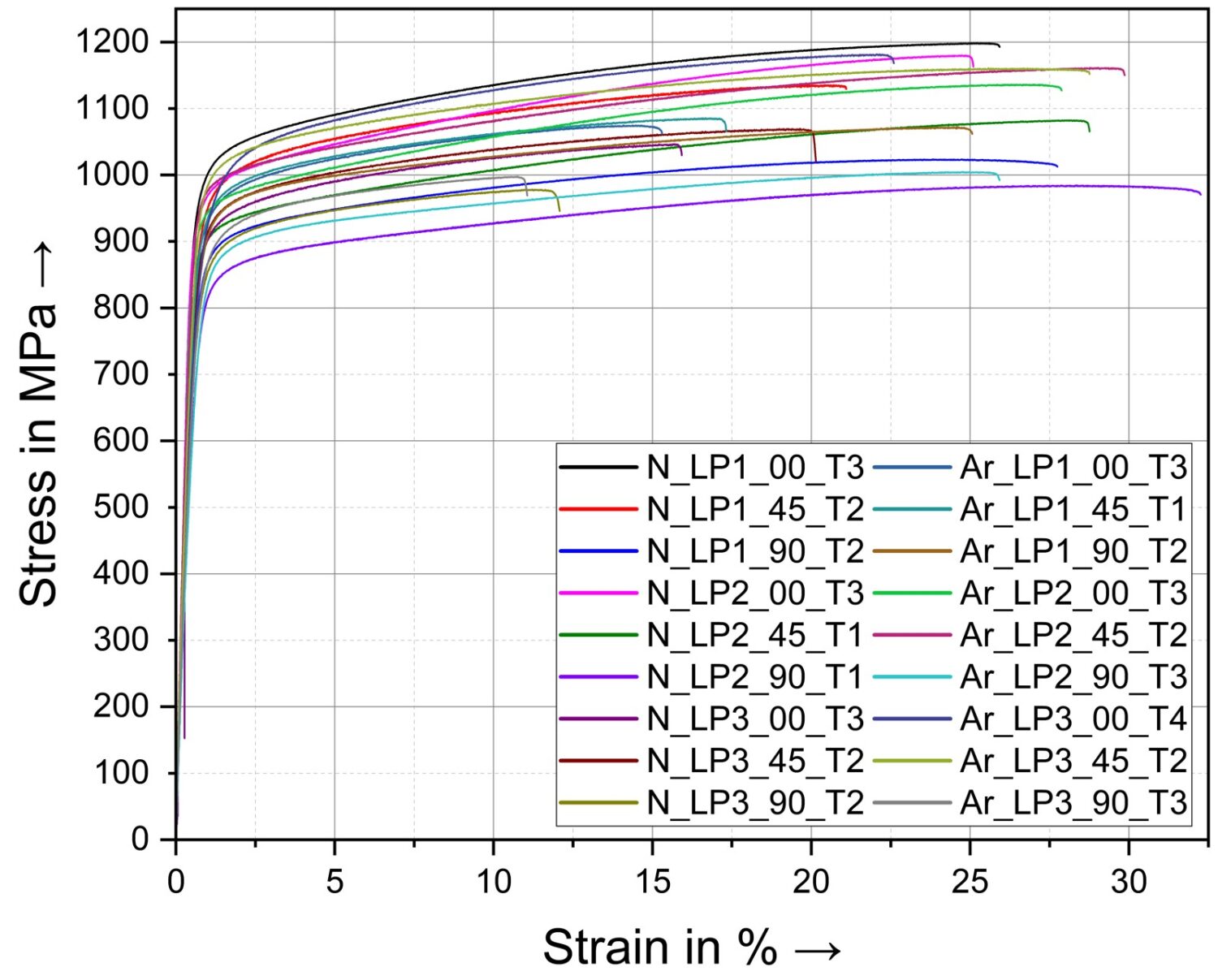

The tensile test campaign for laser parameter study of Printdur HSA® specimens manufactured by LPBF has been completed. For the study, three different laser parameter sets and two shielding gas atmospheres (argon and nitrogen) were used. The three parameter sets were selected to represent (1) a low energy / fast scan speed configuration (reference for low porosity), (2) the previously identified balanced configuration (good compromise between build rate and porosity), and (3) a higher scan speed with the same laser power as in (2) (productivity-oriented). For each condition, tensile specimens were produced with identical geometry and identical post-processing route. Tensile testing was performed at room temperature; the resulting stress–strain curves were evaluated for 0.2% yield strength, ultimate tensile strength, elongation at fracture, and elastic modulus. Table 1 summarizes the key tensile properties for all conditions, and Fig. 1 compares representative engineering stress–strain curves.

Across the investigated parameter window, the balanced parameter sets (2) and (3) delivered the most robust combination of strength and ductility, showing high ultimate tensile strength while maintaining a stable elongation level and comparatively low scatter. The productivity-oriented parameter set (3) reduced ductility in several specimens, which is consistent with a higher sensitivity to local defects. In contrast, the high scan speed low energy parameter set (1) showed the lowest ductility and the largest scatter in tensile properties, indicating an increased likelihood of lack-of-fusion type defects. Fracture consistently occurred within the gauge length.

An influence of the shielding gas was observed. Specimens built under argon generally exhibited improved repeatability of tensile properties and fewer process-related anomalies, consistent with the previously observed reduction in soot formation and spatter within the build chamber. The nitrogen atmosphere produced comparable strength and elongation levels. This suggests that the shielding atmosphere primarily affects process stability, as well as the defect population and surface condition of the specimens.

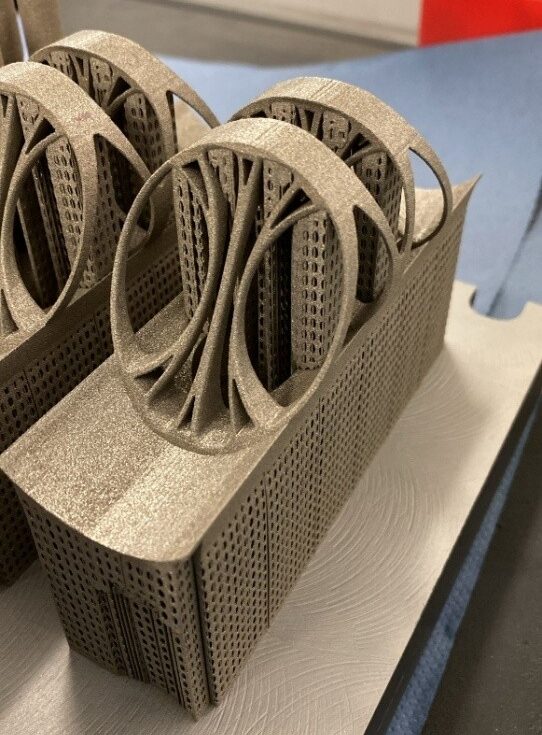

For the collaborative demonstrator H.A.R.R.A.S. (joint work with A07 and C02), initial manufacturing trials have been successfully carried out. The demonstrator aims to validate a hybrid manufacturing strategy for steel framework nodes that combines the geometric freedom and high achievable strength of PBF-LB/M with the high deposition rates of DED-arc. The underlying concept is to manufacture the highly stressed core region of the node using PBF-LB/M in a high-strength alloy, while subsequently building up the remaining volume with DED-arc to reduce overall production time and material waste. Fig. 2 shows the underside of the PBF-LB/M-manufactured core directly after fabrication; the support structures required to ensure dimensional stability and heat dissipation during processing are still present at this stage of the Figure.