Research Summary Report of A06

Laser Powder-Bed Fusion (LPBF) of Steel Elements for Construction – Basics of Design and Mechanical Resilience.

[15.02.2025]

M. Sc. Jakob Blankenhagen Researcher, jakob.blankenhagen@tum.de

Dr.-Ing. Christina Radlbeck Project leader, c.radlbeck@tum.de

Technical University of Munich, TUM School of Engineering and Design, Chair of Metal Structures

The project A06 aims to develop a methodology for producing safe and functional structural steel elements for construction using laser powder-bed fusion (LPBF). The LPBF steel Printdur® HSA will be qualified using and transferring methodologies from material 316L which was investigated in the first funding period. The prediction of fatigue behaviour based on process monitoring data and machine learning will be explored. Lattice structures will be used to tailor the stiffness of the steel elements. These complex LPBF parts will be integrated into large-scale structures, and their joining with conventional construction steel will be investigated. Data for a reliable life cycle assessment of these LPBF parts will be collected during the project.

Current state of research

The first publication on Printdur® HSA is published by A06. In this publication a basis for a better understanding of the material has been established. To this purpose an extensive characterization protocol was implemented, combining both mechanical testing and microstructural analyses. Mechanical tests – including hardness and porosity measurements, tensile tests, and fatigue evaluations – were systematically performed to quantify the material’s performance. Concurrently, the microstructure was thoroughly investigated using techniques such as etched microsection analysis, electron backscatter diffraction (EBSD), and X-ray diffraction (XRD). To complement these analyses, the fracture surfaces of the tested specimens were examined under a scanning electron microscope (SEM) to elucidate failure mechanisms.

The results revealed that Printdur® HSA exhibits exceptional mechanical properties. Specifically, the material demonstrated an average yield strength Rp0.2 of 927.0 MPa, an ultimate tensile strength Rm of 1153.3 MPa, and an elongation at fracture of 38.1 % Thereby, it can be classified as a high-strength, high-ductility austenitic stainless steel. Notably, when compared to conventionally manufactured PBF-LB/M/316L, the (C+N) steel shows remarkable improvements: its average yield strength is 97.2 % higher, while its ultimate tensile strength exceeds that of PBF-LB/M/316L by 122.4 %.

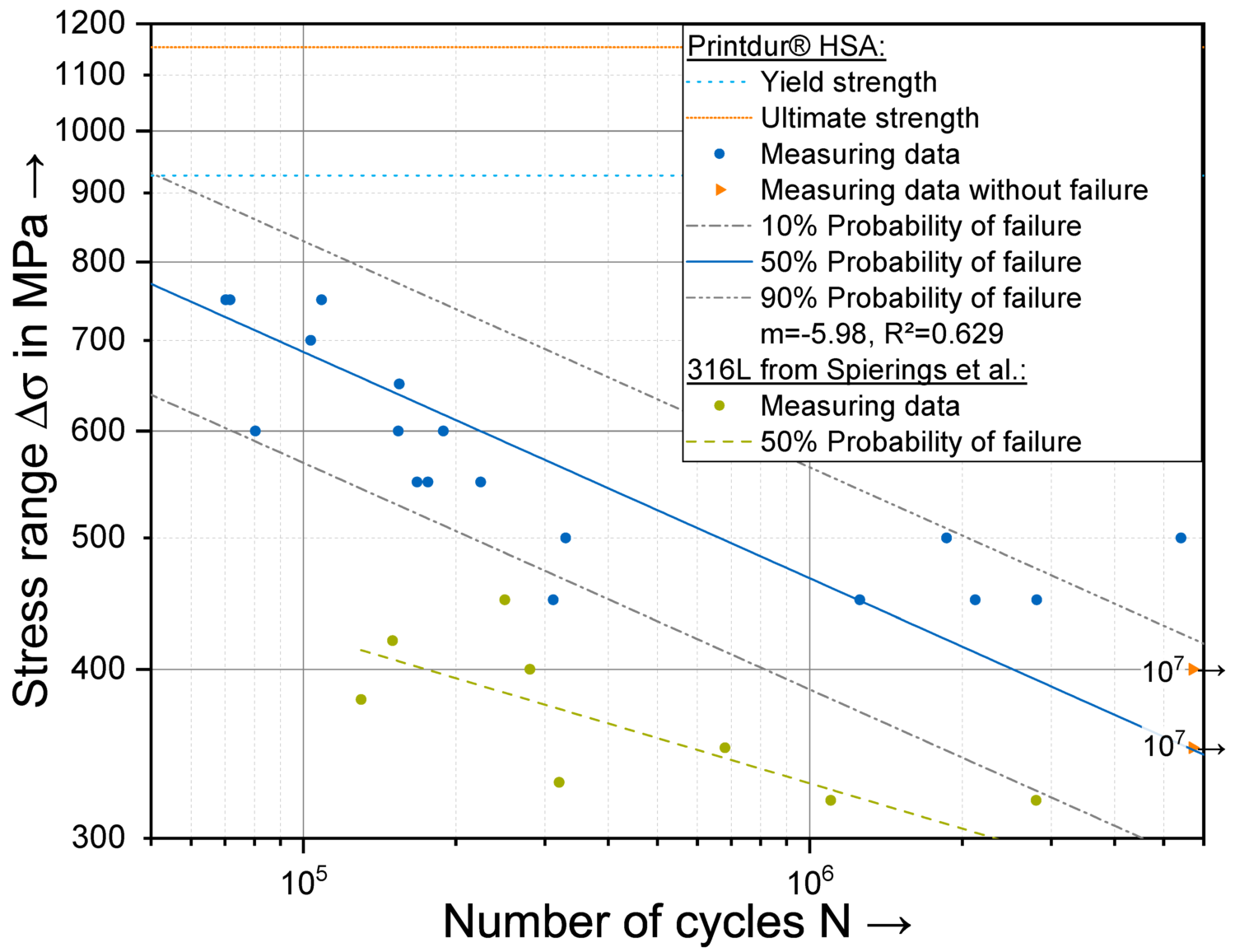

Moreover, a particularly striking outcome of the study is the significantly enhanced fatigue resistance of Printdur® HSA. Under a stress range of 400 MPa, the material endured 25 times the number of cycles compared to PBF-LB/M/316L, underscoring its potential for applications requiring superior durability under cyclic loading conditions. Figure 1 presents the S-N curves for both Printdur® HSA and 316L, clearly illustrating these differences in fatigue behavior.

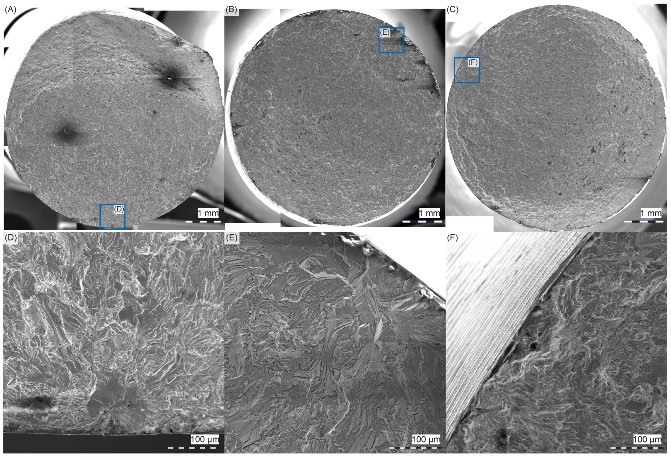

From Fig. 1, it is visible that Printdur® HSA exhibits a higher fatigue resistance. However, the data also reveals considerable scatter at certain load levels, which can be partially attributed to variations in surface topologies. Fig. 2 further illustrates this point by showing the fracture surfaces of specimens tested at a load of 500 MPa. Specifically, the specimen on the left failed after N = 5.410 × 10⁶ cycles, the middle specimen after N = 1.863 × 10⁶ cycles, and the specimen on the right after N = 3.297 × 10⁵ cycles. Analysis of the fracture surfaces indicates that crack initiation occurred within the material for the left and middle specimens. In contrast, the right specimen exhibited a large open pore in a machining groove. This defect likely resulted in a higher local stress intensity factor, promoting early crack initiation and, consequently, premature failure.

Current Publications

- [1] Blankenhagen, J.; Diller, J.; Siebert, D.; Hegele, P.; Radlbeck, C.; Mensinger, M. “Material Characterization of (C+N) Austenitic Stainless Steel Manufactured by Laser Powder Bed Fusion”. Metals 2025, 15, 134. https://doi.org/10.3390/met15020134

- [2] Spierings, A.; Starr, T.; Wegener, K. Fatigue performance of additive manufactured metallic parts. Rapid Prototyp. J. 2013, 19, 88–94.

Fig 1: S-N curve of Printdur® HAS and S-N curve of PBF-LB/M/316L reprinted from [2], stress ratio R = 0.1. [1]

Fig. 2: Scanning electron microscopy (SEM) of fracture surfaces of three fatigue-tested specimens after fracture (Δ𝜎 = 500 MPa): (A,D): specimen F11, N = 5.410 × 106 cycles; (B,E): specimen F12, N = 1.863 × 106 cycles; (C,F): specimen F13: N = 3.297 × 105 cycles; (A–C): whole fracture surfaces, (D–F): estimated failure initiation points. [1]