Research Summary Report of A02

Particle-Bed 3D Printing by Selective Cement Paste Intrusion (SPI) – Particle Surface Functionalisation, Particle Synthesis and Integration of WAAM Reinforcement

[27.09.2024]

Hamilton, Leigh Duncan; Doctoral researcher; L.Hamilton@tu-braunschweig.de

Zetzener, Harald; Leading researcher; H.Zetzener@tu-braunschweig.de

Kwade, Arno; Project leader; A.Kwade@tu-braunschweig.de

All: TU Braunschweig, Institute for Particle Technology

To enable selective paste intrusion (SPI) for practical applications, the inclusion of reinforcement is mandatory. The focus of the first funding period was uniting SPI with wire arc additive manufacturing (WAAM) for reinforced concrete as well as functionalising and/or modifying particulate systems. During the first funding period, two main issues were identified: the need for ecological sustainable development for the combined process of SPI+WAAM and accelerated process velocities to improve the economic efficiency. Therefore, the main goals of the project A02 for the second funding period are optimising ecological materials for SPI and reducing the required number of welding operations within the WAAM process.

Summary

Within A02, we in the working group (WG) Kwade are taking a closer look into various types of recycled, coarse aggregate (sand) particles as well as strategies to increase their packing density as a contribution to a sustainable development of SPI created components. It is, however, of great significance to ensure the aggregate particles conform to requirements for SPI. For recycled aggregates, an abundance of concrete materials from previous structures, especially aggregates with particle sizes smaller than 4 mm, are discarded to date. A02 therefore has the potential to successfully implement recycled aggregates into SPI and prove the suitability of otherwise waste materials. Consequently, commercially available recycled aggregates are one focal point of WG Kwade. Furthermore, concrete components created by SPI are being recycled in-house by milling, sieving, and classifying processes. Recycling SPI components has two main advantages for our research: 1) The concrete mixture including additives is well known for subsequent analysis, 2) Life cycle assessments for SPI products will reveal the true potential of its sustainable development. Albeit, recycled aggregate properties must be aligned with SPI requirements, especially with respect to the particle surface conditions as well as particle size distribution. For instance, coarse aggregate particles covered with cement residues from previous components absorb larger amounts of water, which in turn affects the cement slurry intruding into the particle bed. A reduction in intrusion depth can result unbound layers and, thus, decrease overall concrete component strength.

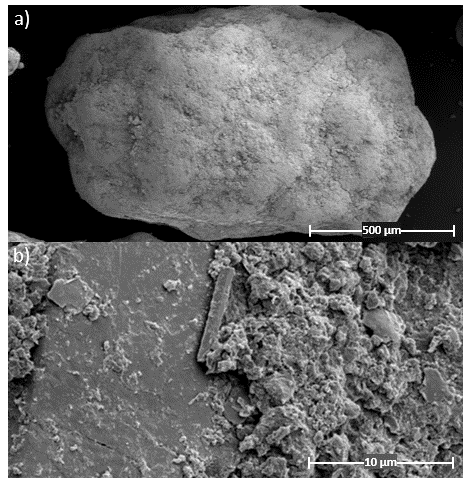

An additional process step was necessary for the smaller components according to SPI recipe. Accordingly, the components were fed either to an impact mill or a two roller mill for initial comminution. The significant factor here lies within investigating appropriate stress mechanisms during milling for the components. If the impact or stress is too high, the components shatter into much finer pieces than the initial size of the coarse aggregate particles. Hence, the goal is to restore the initial components with the highest possible purity as well as initial particle structure. Figure 2 exhibits high-resolution images of an aggregate particle with hardened cement on its surface. Thus, further recycling steps are necessary to improve the aggregate particle purity.

Current state of research

Within the given context, first experiments were performed with commercially available recycled aggregates (< 4 mm), smaller components mixed with a standard SPI recipe, and quartz typically used in SPI as a reference material, ranging from 0.7 mm to 3.2 mm. The commercially available recycled aggregates were sieved into three size fractions within the aforementioned range, which were generally applied in previous research. By doing so, fines were removed from the bulk material, which would otherwise hinder slurry intrusion. Larger impurities (see Figure 1) were removed from the resulting bulk materials before further analysis.