Overview AMC Researchers

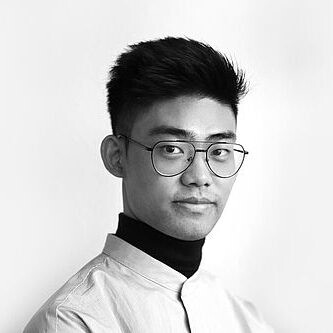

has a background in industrial engineering and biomimetics. Currently he is a doctoral student at the Chair of Materials Handling, Material Flow, Logistics within TUM and is responsible for the design, automation, and advancement of the near-nozzle continuous mixing system that was developed during the first project phase of A03.

Project(s)

Extrusion of Near-Nozzle Mixed Concrete –Individually Graded in Density and in Rate of 3D Fibre Reinforcement

Publications

All publications from M. Sc. Michael UnterreinerPublications from M. Sc. Michael Unterreiner

Publications

has a background in lightweight structures’ design and computational mechanics. Currently, she is a doctoral researcher at the Institute of Structural Analysis at TU Braunschweig with a focus on embedded finite element techniques and applications in multi-physics simulations and structural optimization. Within project C02, Franziska mainly contributes to the high-fidelity optimization approach.

Project(s)

3D Structural Puzzle – Numerical Multi Scale Shape and Topology Optimisation Methods to Additively Manufacture Optimal Structures from Optimised Pieces

Publications

All publications from M. Sc. Franziska WahlPublications from M. Sc. Franziska Wahl

Publications

He is a Senior Scientist and Head of the Computational Simulation Lab at the Chair of Structural Analysis, Technical University of Munich. With a robust background in computational mechanics, structural mechanics, optimization, and fluid dynamics, his research centers on advancing and implementing cutting-edge continuous optimization techniques within the framework of the C02 project. In addition to his academic leadership, he serves as a technical committee member of the open-source KRATOS Multiphysics finite element framework, which plays a pivotal role in the development efforts of the C02 project.

Project(s)

3D Structural Puzzle – Numerical Multi Scale Shape and Topology Optimisation Methods to Additively Manufacture Optimal Structures from Optimised Pieces

Publications from Dr.-Ing. Suneth Warnakulasuriya

Publications

2026 | J. Müller, H. Jahns, M. Müggenburg, K. Thiele, J. Unglaub, J. Hensel: Case study report on design, manufacturing and digital representation of a DED-Arc steel node for construction Sci Rep 16, 3263, 2026, https://doi.org/10.1038/s41598-026-37315-2

Data | Zenodo, 2026, https://doi.org/10.5281/zenodo.17192191

Is a doctoral researcher at the Institute of Structural Design (ITE) at TU Braunschweig.

Project(s)

Injection 3D Concrete Printing (I3DCP) – Material Efficient Lightweight Reinforced Concrete Structures Based on Spatially Complex Strut-and-Tie-Models

Publications

All publications from M. Sc. Yinan XiaoPublications from M. Sc. Yinan Xiao

Publications

is a civil engineer and doctoral researcher at the TU Braunschweig Institute for Structural Design (ITE). She is responsible for Project A10, where she is conducting research on Sprayed Earth Additive Manufacturing (SEAM). Her work involves exploring earthen construction techniques, enhancing the SEAM process, and optimizing material-process interactions. Within this project, she focuses on material development through experimental studies, data analysis, and investigating material behavior to identify and optimize the key parameters of the SEAM process.

Project(s)

Earth Additive Manufacturing (EAM) – Material and Process Combinations for AM with Earth-based Materials

Publications

All publications from M. Sc. Diana ZavaletaPublications from M. Sc. Diana Zavaleta

Publications

deputy director of the institute for particle technology, head of Division Powder and Slurry Processes, supports Prof. Kwade in leading the project.

Project(s)

Particle-Bed 3D Printing by Selective Cement Activation (SCA) – Sustainability, process enhancement and material models

Particle-Bed 3D Printing by Selective Cement Paste Intrusion (SPI) – Particle Surface Functionalisation, Particle Synthesis and Integration of WAAM Reinforcement

Publications

All publications from Dr.-Ing. Harald ZetzenerPublications from Dr.-Ing. Harald Zetzener

Publications

2025 | N. Meier, F. Herding, H. Zetzener, I. Mai, D. Lowke, A. Kwade: Surface modification of bulk material for particle bed 3D concrete printing – Effect on wettability, porosity, and mechanical properties Advanced Powder Technology, 2025, https://doi.org/10.1016/j.apt.2025.105123

Data |Zenodo, 2025, https://doi.org/10.5281/zenodo.17641009

2024 | L.D. Hamilton, H. Zetzener, A. Kwade: The effect of process parameters on the formulation of a dry water-in-air dispersion Advanced Powder Technology, 35(7), 2024. https://doi.org/10.1016/j.apt.2024.104553

Data | Dataset for the Processing of a Dry Water-in-Air Dispersion, LeoPARD, 2025, https://doi.org/10.24355/dbbs.084-202503271305-0.

2023 | D. Talke, B. Saile, N. Meier, F. Herding, I. Mai, H. Zetzener, A. Kwade, D. Lowke: Particle-bed 3D printing by selective cement activation – Influence of process parameters on particle-bed density. In: Cement and Concrete Research, 168. (2023)

https://doi.org/10.1016/j.cemconres.2023.107140

2022 | Hamilton, L. D.; Zetzener, H.; Kwade, A.: The Effect of Water, Nanoparticulate Silica and Dry Water on the Flow Properties of Cohesionless Sand. In: Processes 2022, 10, 2438. https://doi.org/10.3390/pr10112438