News

Research Summary Report of B04

Category: Research Summary Report

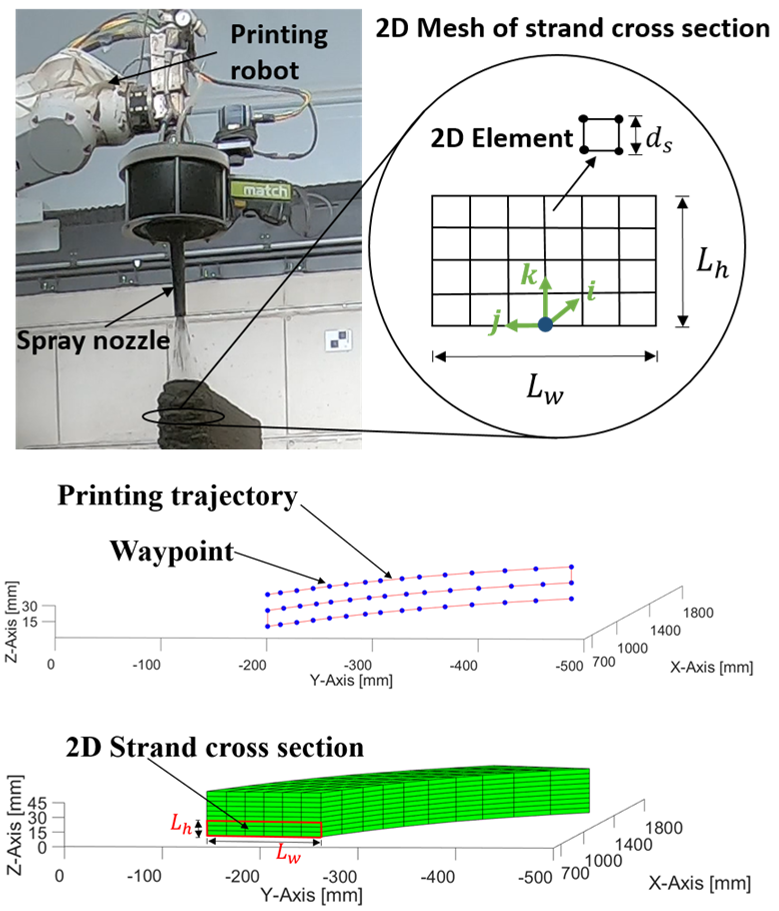

Process Control and Adaptive Path Planning for Additive Manufacturing Processes Based on Industrial Robots with an Extended Degree of Freedom [11.01.2023] Ekanayaka, Virama; Doctoral researcher, v.ekanayaka@tu-braunschweig.de, Hürkamp, André; Project Leader, a.huerkamp@tu-braunschweig.de, TU Braunschweig, Institute of Machine Tools and Production Technology (IWF) The integration of robot-guided additive manufacturing in the construction industry increases the degree of automation and can thus lead to an increased productivity and increased component quality. In shotcrete 3D printing (SC3DP), reproducible manufacturing results and ensuring component quality are major challenges, as the properties of shotcrete depend on many different parameters (e.g. temperature, pressure, water-cement ratio, hardening accelerator). The goal of this research project is to develop a reproducible, robot-guided shotcrete process based on multi-model adaptive path …

AMC Highlights 2022

The Collaborative Research Centre TRR 277 Additive Manufacturing in Construction (AMC) looks back on an eventful and successful year. Intensive scientific exchange, innovative research approaches, new research infrastructure and many awards for outstanding research: in 2022, the AMC had it all, and so it can continue. Some AMC Highlights had a special focus on the next generation in civil engineering and architecture. For example, the AMC was part of the nationwide Digitaltag 2022 and Girlsday, getting young people excited about 3D printing research. The AMC has acquired a taste for it and is keen for more: more contact with school students, more open labs, more presentations of innovative research in 2023. At this year’s Digital Concrete (DC 2022) in Loughborough, …

Workshop on materials and processes with AMC-Mercator-Fellow Dr. Nicolas Roussel

Workshop on materials and processes with AMC-Mercator-Fellow Dr. Nicolas Roussel From November 30th to December 1st, AMC-Mercator-Fellow Nicolas Roussel, was visiting Technische Universität Braunschweig and the TRR 277 AMC for a workshop on “Materials and Processes in Additive Manufacturing”. Nicolas Roussel is an expert in the field of rheology and additive manufacturing and the RILEM President. The workshop was held at the iBMB of the TU Braunschweig (headed by Prof. Dirk Lowke) in cooperation with the ITE (headed by Prof. Harald Kloft). The goal of the workshop was to present and discuss current research topics of PhD students and research associates working in these areas and to clarify important open questions. Topics included: – Testing of freshly printable material – …

Research Summary Report of C06

Category: Research Summary Report

Integration of Additive Manufacturing in the Construction Process [23.12.2022] Mawas, Karam; Doctoral researcher, k.mawas@tu-braunschweig.de, Gerke, Markus; Project leader, m.gerke@tu-braunschweig.de, Maboudi, Mehdi; Associated scientist, m.maboudi@tu-braunschweig.de, TU Braunschweig, Institute of Geodesy and Photogrammetry (IGP) Main goal In order to ensure that a robust process is followed and the printed object adheres faithfully to the designed model, continuous and automatic data capturing and inspection of the process is required. Quality control also ensures that the combination of components into objects can be realized. Summary As a result of variations in manufacturing processes, specimens may differ from their as-designed models. Therefore, all manufacturing steps should be equipped with a proper quality control process. Although quality control of a printed specimen is mainly about …

Research Summary Report of A03

Category: Research Summary Report

Extrusion of Near-Nozzle Mixed Concrete –Individually Graded in Density and in Rate of 3D Fibre Reinforcement [09.12.2022] M.Sc. Dahlenburg, Maximilian; TP editor, maximilian.dahleburg@tum.de, Prof. Dr.-Ing. Fottner, Johannes; Project leader, j.fottner@tum.de, TUM, Chair of Materials Handling, Material Flow, Logistics The main goal of A03 is to establish a novel concrete extrusion process using a near nozzle mixing (NNM) process to enable the change and non-discrete gradation of material and its properties during printing. With this approach multi-functional and multi-material parts can be printed, with an overall higher building rate due to a lower workability demand of the process and higher structuration rates of the used materials. Printed parts can thus simultaneously fulfill load-bearing and thermal insulation functions by locally changing the material properties. Thus, the …

Research Summary Report of A01

Category: Research Summary Report

Particle-Bed 3D Printing by Selective Cement Activation (SCA) – Particle Surface Functionalisation, Particle-Bed Compaction and Reinforcement Implementation [25.11.2022] Meier, Niklas; Researcher, niklas.meier@tu-braunschweig.de Zetzener, Harald; Leading researcher, h.zetzener@tu-braunschweig.de Kwade, Arno; Project Leader, a.kwade@tu-braunschweig.de all: TU Braunschweig, Institute for particle technology The main goal of our research in project A01 is to improve the mechanical strength and shape accuracy of the printed concrete parts as well as the printing speed. While our work at the iPAT is improving the powder properties the project partner iBMB focuses on the material-process interaction. Summary Previous research has shown, that higher component densities often lead to higher compressive strength in selective cement activation. As shown in the previous research summary report, the former work aimed …

Fun with technology! – LabDay on 27 January 2023

Category: Press Room

Fun with technology! – LabDay on 27 January 2023 Fun with technology! What is possible with a 3D printer? What are the challenges of digital construction? With the LabDay, the Collaborative Research Centre TRR 277 Additive Manufacturing in Construction (AMC) make female students aware of the possibilities of 3D printing for architecture and for the entire construction industry. In the workshop, the young people learn about the digital fabrication process from design to production. And it will be very hands-on: the students digitally design an object themselves, which is then printed with clay. The LabDay on 27 January 2023 is suitable for female students from grade 11. Interested? Then simply contact the AMC at the following e-mail address: m.baehrens@tu-braunschweig.de. Find …

Research Summary Report of C03

Category: Research Summary Report

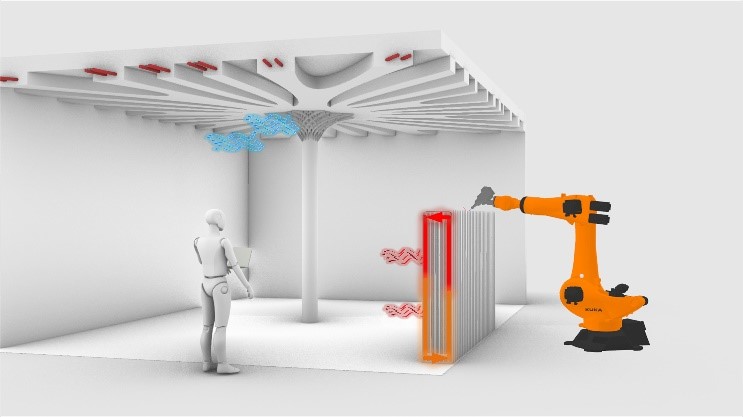

Integration of Passive and Active Functions in Additively Manufactured Construction Elements [18.11.2022] Auer, Thomas; PL, thomas.auer@tum.de Briels, David; doctoral researcher, david.briels@tum.de Nouman, Ahmad; doctoral researcher, ahmad.nouman@tum.de all: Technical University of Munich, TUM School of Engineering and Design, Chair of Building Technology and Climate Responsive Design This research explores the potential of AM for building components with (a) directly incorporated active performative features (e.g. ventilation, thermal activation, or building services distribution), as well as (b) passive design strategies (e.g. thermal insulation, sound insulation, acoustics, or controlled solar gains) via material and geometric differentiation. The objectives are a more robust building operation, reducing embodied and operational carbon emissions, and improving user comfort, achieved by a more holistic, climate-aware, and fabrication-aware design, …

Research Summary Report of B05

Category: Research Summary Report

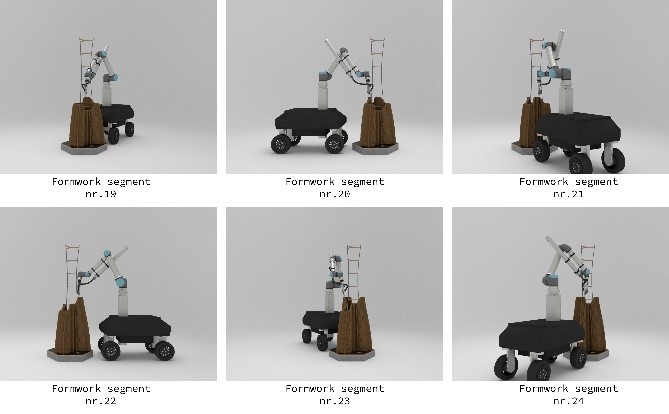

Principles of Mobile Robotics for Additive Manufacturing in Construction [21.10.2022] Dielemans, Gido; Doctoral researcher, gido.dielemans@tum.de, Technical University of Munich, Department of Architecture, TT Professorship Digital Fabrication This research examines the architectural implications of mobile robotics for AM in construction and develops methods for their implementation. The material deposition method of clay and concrete extrusion 3D printing is used to investigate mobile part-based AM strategies, that is, to produce large objects whose size exceeds the static workspace of the robot. By implementing advanced sensor and control solutions, autonomous localization and precise manipulation techniques for mobile AM are explored. In addition, this research aims to provide scalability to AM processes by examining the use of multiple robots to collaborate on single …

Research Summary Report of A08

Category: Research Summary Report

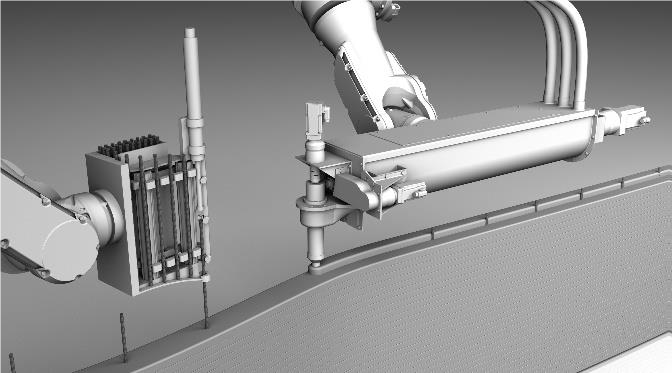

Structural Timber by Individual Layer Fabrication (ILF) [14.10.2022] Buschmann, Birger; Doctoral researcher, birger.buschmann@tum.de, Talke, Daniel; Doctoral researcher, talke@tum.de Henke, Klaudius; Project leader, henke@tum.de Technical University of Munich, Chair of Timber Structures and Building Construction The main goal of the project ‘A08 -Structural Timber by Individual Layer Fabrication (ILF)’ is to develop a process to additively manufacture large-scale, wood composite objects with a maximum content of wood material and strength values suited for applications in construction. In the course of the project multiple process variants and material combinations are explored. For this, the necessary machinery is developed in iterative steps and the mechanical properties of the resulting objects as well as the geometric capacity of the processes are investigated. Finally, …

Research Summary Report of A04

Category: Research Summary Report

Integrated Additive Manufacturing Processes for Reinforced Shotcrete 3D Printing (SC3DP) Elements with Precise Surface Quality [11.11.2022] Freund, Niklas; doctoral researcher, n.freund@ibmb.tu-bs.de Lowke, Dirk; project leader, d.lowke@ibmb.tu-bs.de all: TU Braunschweig, Institute of Building Materials and Concrete Construction and Fire Safety (iBMB) Project A04 investigates cooperative Additive Manufacturing (AM) processes based on Shotcrete 3D Printing (SC3DP) for the production of material-efficient, force-optimized, reinforced, load-bearing concrete components with precise surface quality and high geometric precision. The goal is to produce large-scale concrete elements using significantly lower amounts of reinforcement and concrete as compared to standard concrete construction principles. Summary In SC3DP applications, the precise control of rheological material properties represents a necessity. Here, data based rheological material models are required that allow the …

Research Summary Report of A05

Category: Research Summary Report

Integration of Individualized Prefabricated Fibre Reinforcement in Additive Manufacturing with Concrete [02.11.2022] Gantner, Stefan; Scientific Researcher, stefan.gantner@tu-bs.de, TU Braunschweig, Institute of Structural Design (ITE) Summary Cement-based additive manufacturing techniques need to be enhanced by the ability of integrating reinforcement, in order to fulfil requirements of construction. This project focuses on non-metallic continuous fibre reinforcement, which is not only corrosion resistant but also flexible in handling. Instead of bending and welding, glass or carbon fibre rovings can be processed by winding onto a support structure. Based on three fundamental AM-principles, namely material jetting and extrusion, as well as particle bed printing, a set of winding concepts for integrating reinforcement has been developed. Within a holistic framework all relevant aspects from …

Research Summary Report of A02

Category: Research Summary Report

Particle-Bed 3D Printing by Selective Cement Paste Intrusion (SPI) – Particle Surface Functionalisation, Particle Synthesis and Integration of WAAM Reinforcement [28.10.2022] Riegger, Felix; Doctoral researcher; Felix.Riegger@iwb.tum.de Wimmer, Andreas; Head of the research group; Andreas.Wimmer@iwb.tum.de All: Technical University of Munich, Institute for Machine Tools and Industrial Management The main goal of project A02 is the implementation of reinforcement with Wire and Arc Additive Manufacturing (WAAM) in concrete elements produced by Selective Paste Intrusion (SPI) by means of a simultaneously additive manufacturing process. The combination of SPI and WAAM is accompanied by obstacles that must be overcome to ensure the collaborated functionality. One major challenge occurs from the high energy input of WAAM (temperatures up to 1600 °C), which negatively affects …

#11 Quarterly meeting at the AMC – quo vadis?

-english version below- Mitte Oktober trafen sich rund 80 Wissenschaftler:innen des Sonderforschungs-bereichs / Transregio 277 – Additive Manufacturing in Construction (AMC) im Rahmen Ihres 11. Quartalstreffens, um den aktuellen Projektstand der Teilprojekte zu präsentieren und zu diskutieren. Dabei lag der Fokus nicht nur auf – Was hat der AMC bis hierhin erreicht? sondern besonders auf – Was sind die nächsten Ziele des AMCs? Zentrale Aspekte des Treffens waren dabei besonders die etablierten und neu entwickelten Netzwerke zwischen den einzelnen Teilprojekten und die Planung von mehreren konkreten gemeinschaftlichen Anschauungsobjekten, sogenannten Demonstratoren. Die Erweiterung der bestehenden Netzwerke und die Entwicklung der Demonstratoren gehen hier Hand in Hand und verstärken die Zusammenarbeit der drei Focus Areas des AMCs. Die prozess- und materialorientieren Projekte …

Journalist of the computer magazine c´t visited the AMC

Category: Press Room

Journalist of the computer magazine c´t visited the AMC We are excited! The AMC – TRR 277 is in the latest issue of c’t. Europe’s largest IT- and tech- magazine from Heise Verlag (heise online) visited the AMC at the end of September and we talked about the research of the AMC, the special features of 3D-printing in construction and the potential it offers. Now the exciting article on the topic -Revolution in construction: 3D printing saves material and enables new forms- has been published in the current issue. Many thanks to Kathrin Dörfler, Harald Kloft, Dirk Lowke, Dr. Norman Hack and Janna Vollrath for your interviews and input. You can find the article here: https://www.heise.de/select/ct/2022/23/2224916053682196709 …

Research Summary Report of C06

Category: Research Summary Report

Integration of Additive Manufacturing in the Construction Process [06.10.2022] Placzek, Gerrit; Doctoral researcher, g.placzek@tu-braunschweig.de TU Braunschweig, IBB The integration of additive manufacturing into construction requires an interdisciplinary approach. The different competences of the team – digital fabrication in architecture (Hack), geodesy and photogrammetry (Gerke) and construction management (Schwerdtner) – lead to research from diverse perspectives on the various scalar levels of construction to be viewed holistically: component, building and industry scale. Within Subproject C06, our goal is to create a continuous digital and lean-based process chain from design (using BIM method) to fabrication (using AM method). Based on process models, we investigate construction processes and how to change them into a construction industry 4.0. Summary The most well-known approach …

AdvanceAEC Autmn School 2022 – First Impressions

Category: Press release

AdvanceAEC Autmn School 2022 – First Impressions At this year AdvanceAEC autumn school the AMC-Researchers Noor Khader, Gido Dielemans and Lukas Lachmayer hold a full-day workshop “revAMp – Additive Manufacturing in Construction: In situ Retrofitting Using AM with Mobile Robots”. In this workshop young scientists going to experimentally explore whether the deployment of mobile robots on building sites could be utilized for retrofitting, customized renovation, or repair by applying in situ extrusion 3D printing technology. The AMC is part of the AdvanceAEC network and the Autmn School is aimed at early career researchers, e.g. master students, PhD students and postdocs from the partner institutions of our network. This year’s AdvanceAEC Autumn School is hosted by IntCDC and is part of …

Research Summary Report A07

Category: Research Summary Report

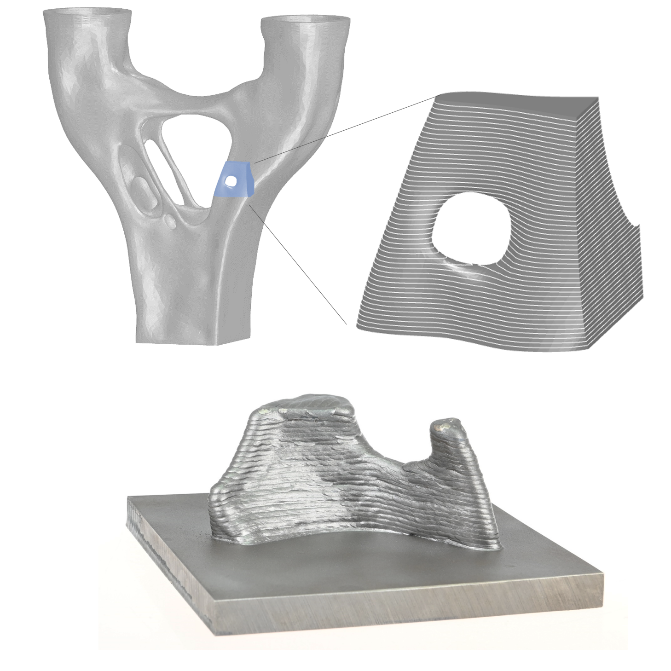

Wire and Arc Additive Manufacturing (WAAM) of complex individualized steel components [30.09.2022] Müller, Johanna; doctoral researcher johanna.mueller@tu-braunschweig.de TU Braunschweig, Institute of Joining and Welding Main goal The aim of TP A07 is the design, the manufacturing and the testing of complex individualized steel components by means of WAAM. That contains the fundamental investigation of design and the design process for WAAM components. For the manufacturing of steel components by WAAM, stable and reliable processes for basic geometries are qualified and based on that, case study demonstrators for the identification of manufacturing restraints are fabricated. Furthermore, a novel approach for material and component testing is developed to identify local material and component properties. Summary The aim of WG Hensel …

FLOWall wins at the ICONIC AWARDS 2022: Innovative Architecture

Category: Press release

The AMC is part of the succesful project FLOWall The FLOWall project receives the Iconic Award 2022: Innovative Architecture for its visionary concept. The innovative design of the cooperating scientists Robin Dörrie, Gabriela Kienbaum, Dr. Vittoria Laghi, Lidiana Arrè, Neira Babovic, Prof. Dr. Harald Kloft and Prof. Dr. Norman Hack, TU Braunschweig and University of Bologna wins in the category – CONCEPT – Visionary Architecture. With its novel approach to coastal protection, the project pursues the use of digital technologies for the individual and ecological design of urban coastal protection structures (CPS). FLOWall convinced the jury with its approach of novel combination of different additive manufacturing processes i.e. shotcrete 3D printing(SC3DP) and Wire Arc Additive Manufacturing (WAAM). Their combined use …

Research Summary Report C05

Category: Research Summary Report

Jointing Principles for Combination of Concrete Elements Produced by Different Additive Manufacturing Processes [23.09.2022] Empelmann, Martin; Project Leader, m.empelmann@ibmb.tu-bs.de Weigel, Hendrik; Doctoral Researcher, h.weigel@ibmb.tu-bs.de TU Braunschweig, Institute of Building Materials, Concrete Construction and Fire Safety (iBMB), Division of Concrete Construction Main goal The main goal of the C05 project is gaining fundamental knowledge for the design of dry joints in AM components. Therefore, the correlation between the execution and manufacturing on the load-bearing behaviour of dry joints will be investigated. Many different joint geometries are gathered, compared and evaluated by experimental testing and numerical methods. Summary The selected joint profiles from the so-called joint catalogue (see last RSR) are tested in terms of their compressive load-bearing behaviour. The …